Versatility of Laser Cutting Machines in Industries

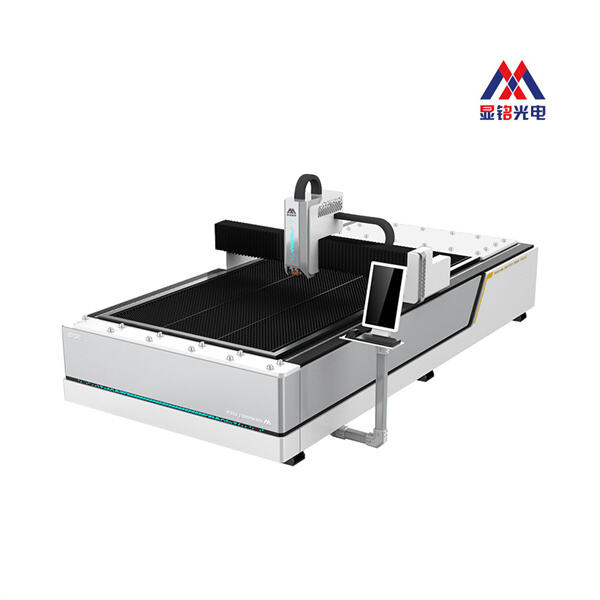

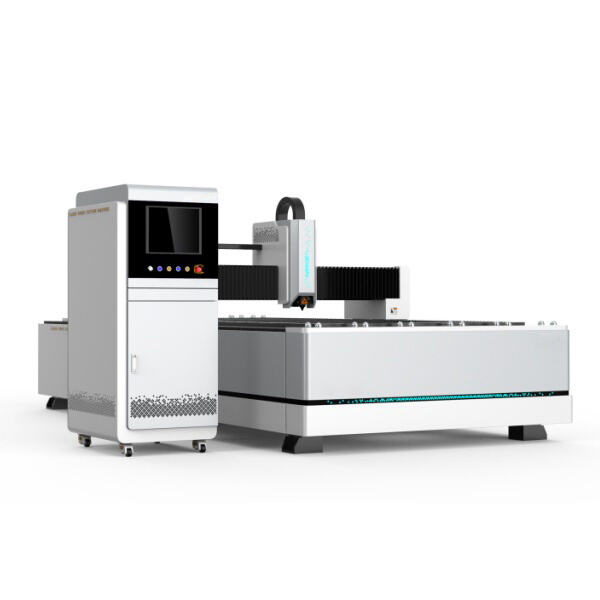

Laser cutting machines have been extremely useful devices that allow one to cut through an array of materials with absolute precision and incredible speed. Due to its ability too not only cut material but also engrave, mark and etch it these Liaocheng Xianming laser cutter cutting machine are well appreciated across various industries.

Lately, different industries have been leaning toward laser cutting machines for their accuracy and efficiency. In the automotive sector, for example, they are ideal for when you need to cut steel and aluminum into very high-quality car parts. Also in the aerospace industry, as well as medical device industries where laser cutting technology provides precision and consistency that can be invaluable.

Laser cutting machines can cut lots of materials - metals steel, aluminum (including other alloys), copper and brass are preeminent; and spare plastics, composites, wood carbon fiber cloth, polystyrene fabrics rubber waxes ceramics quartz glass granite marble titanium per se even a whitepaper. Different types of lasers are used - CO2, fiber, and YAG lasers which are equipped to work with specific materials. For example, a CO2 laser can cut wood, plastic and acrylic; Liaocheng Xianming laser cutting machine industrial are best used to cut metal such as steel and aluminum.

Laser machines are used to cut materials as well engrave them or etch for desired branding and labeling of products. This attribute is quite productive for tailored production industries these kinds of as metalworking, woodworking and products administration. Once smooth wood is damaged, no fixing it Laster engraving and etching.

Small And Medium Cutting Machine Producers Benefit from Laser Cutting Machines The manufacturing process is done with high precision through these machines, and production can be accelerated to meet deadlines, working with a gamut of materials. Zero Waste Compared to Traditional Cutting - which also saves you money in the long-run on waste disposal. Though laser cutting machines are expensive upfront, they enable manufacturers to enhance their output quality and offset the costs.

Liaocheng Xianming machines market and sales network in over 60 countries and areas, has a logistics being professional procedure which provides clients with speedy transportation services so that logistics is manufactured easier. We are going to do our safer to make fully sure your fiber laser machine is delivered efficiently and swiftly, whether you're private business a person.

Liaocheng Xianming is very attentive to after-sales and support services, knowing that having excellent service for fiber lasers for us are equally vital. We stick to the principles that are the spirit of customer-centricity and global presence. This is made possible through support for our service networks.

Liaocheng Xianming can provide clients and logos as well since other personalized and agents with images for the customer's logo, product, videos as well as other items. Our fiber laser machine has a top quality than|top quality} other providers, our primary merchandise include a wide range of high-powered metal laser cutting machines, laser welding machine, cleaning machine, and co2 engraving machine and marking machine.

Liaocheng Xianming covers a 30000 place square meters of factory, has an excellent r D team into the field. We are centered on the developing and design for assorted fiber lasers. We have several often patents technical have passed the IS09001 quality management certification system because well as European CE certification plus FDA certification.

The Laser cutting machines have brought a radical change in the operations and thus are used by industry pro over old style machining methods facilitating numerous advantages throughout production. These tool, having an advanced technology have become necessary equipment in divers sectors that enhance productivity and quality of the output.

High precision is one of the most critical benefits that laser cutting machines provide, thereby decreasing post-production changes. The machines guarantee top-quality final products with accuracies in microns, which makes them the go-to choice for industries that seek perfection and sophistication-most components produced are just minuscule.

Laser machines effectively reduce the processing time in manufacturing, since these are faster than other traditional methods of cutting. These machines decrease the cutting and engraving time which ultimately results in operational efficiency as well as more productivity.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog