Industrial applications of a laser welding machineGraphics industries using the services of these units [help to fill in this segment as properly it is fine or no?]Increased acceptance for high-precision needs Demand for these machines is very high so the prices of this machines soared. This article will explain why these laser welders are demanded and if you need to think of investing in a high-end laser welding machine.

Why Does a Laser Welding Machine Cost More Today?

Increasing demand for Laser Welding Machines Due to its accuracy and speed, laser welding provides robust performance which is why it has been used as a dependable weld technology in many industries such as automotive, aerospace or electronics. The more these machines are demanded, the costlier they become. Part of the reason those prices are climbing is they must cover more balance-of-system costs and manufacturing with a greater degree of complexity, such as producing laser welding machines. While the production cost is increasing due to the price of accessing advanced technology and specialized expertise. Also, the cost of raw materials used in making has gone up as well.

Laser welding machines, like all industrial equipment with different features and functionality come at a price - both the literal monetary cost as well as the delay to economic benefits. Brands such as JINAN GT and MORN are one of a few cost-friendly alternatives, with machines in the $6k to 15K range. TRUMPF and Amada Miyachi: These high-end welding machines might cost you up to $200,000 (or higher). The advanced features of these premium machines can weld complex geometries in diverse range materials and come with automated functions, online monitoring.

Purchasing an expensive laser welding machine could greatly compliment your productivity, quality and efficiency. These machines utilize next level technology to increase accuracy, speed up manufacturing and reduce mistakes. In addition, they also provide cost reductions on maintenance and long-lasting benefits over the cheap ones. That said, be sure to analyze your businesses needs before purchasing a top-dollar machine. If your operations do not justify the investment in a high-end model, then you should consider only purchasing a basic machine. Also Keep in Mind, Premiums usually do not have lowest odds of operation and eventually higher maintenance bill against time

The price of laser welding machines is influenced by various factors

Some factors affect the price of laser welding machine:

The types of materials the machine can weld – Typically, the more materials a given welding machine is capable of working with, generally speaking these will be higher priced.

Layer power — Greater laser strength calls for higher cost of the machine.

Workspace Size: Larger work area equals higher priced machine.

The degree of automation — Machines that have various automatic functionalities are costlier than manual machines

Brand and manufacturer:Price of a product is determined by the respective brand or company that created them.

If you are one of the buyers seeking cheaper options, then worry not as there is a laser welding machine for sale which can offer excellent results without breaking your bank! There are a few alternatives you could outline:

JINAN GT-HB1500 Laser Welding Machine – Perfect for small and medium scale businesses, which can weld on stainless steel, titanium a certain aluminium.

MORN Handheld Fiber Laser Welding Machine –-Metal, Gold or Silver Copper, Melt Jewelry Spot WelderFirstly, this is a simple blue-white portable fiber laser welding machine for small metal parts you can think of.

Ever Laser Pulse Series Welding Machine – Cost-effective and suited for welding multiple materials- gold, silvertitanium, stainless steel. It runs using 100 J power and can perform welding speeds up to 120 Hz.

Growing demand, alongside production costs that are increasing fuel the rising prices of laser welding machines. So, you may want to go with a bit of comparison before investing in this heavy-duty laser welding machine. High-end machines This offer advanced features that can greatly improve your business operations, but it is important to make sure the machine capabilities align with what specifically you need. There are also more budget-friendly options to get started with basic functionality at a lower price point.

Liaocheng Xianming pays much attention to after-sales and support services, knowing that having the quality of service provided by fiber-laser machines for us is equally vital. We will follow the principles in keeping with a global and customer-focused presence, which is bolstered by support for the service network.

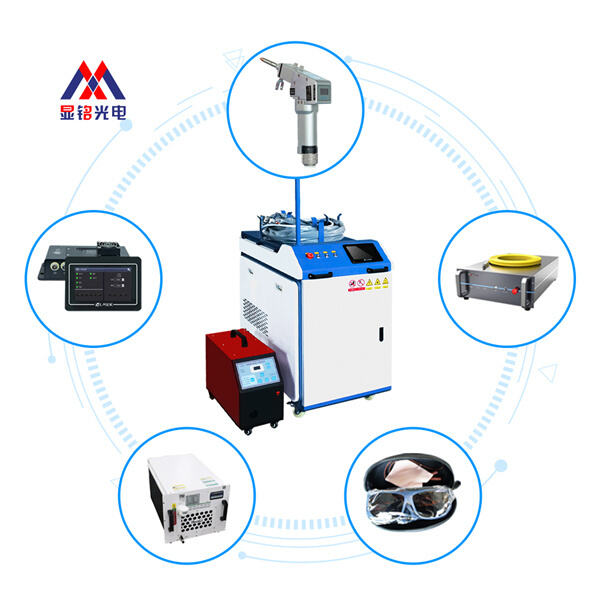

Liaocheng Xianming produces customers with personalized logos plus videos, images and other materials. Agents also provide customized items by customers. Our fiber laser machine tend to be more advanced than more manufacturers, our main services and products include a wide range of high-powered metal laser cutting machines laser welding machine, cleaning machine, and co2 engraving machine, marking machine.

Liaocheng Xianming has a 30000sqm manufacturing unit. We want the top r D department in the industry, therefore we look at the creation of various kinds of fiber lasers.

Liaocheng Xianming machines sales plus marketing network that spans over 60 countries and regions. It provides a professional logistics process that provides customers with quick transportation services, making sure logistics gets to be more convenient. Regardless of whether your are the consumer or simply business we are going to endeavour to be the ideal at meeting your needs and acquire the fiber laser machine to where it requires to securely be quickly and.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog