Laser power: 1000w 1500w 2000w

Laser running mode: continuous clean

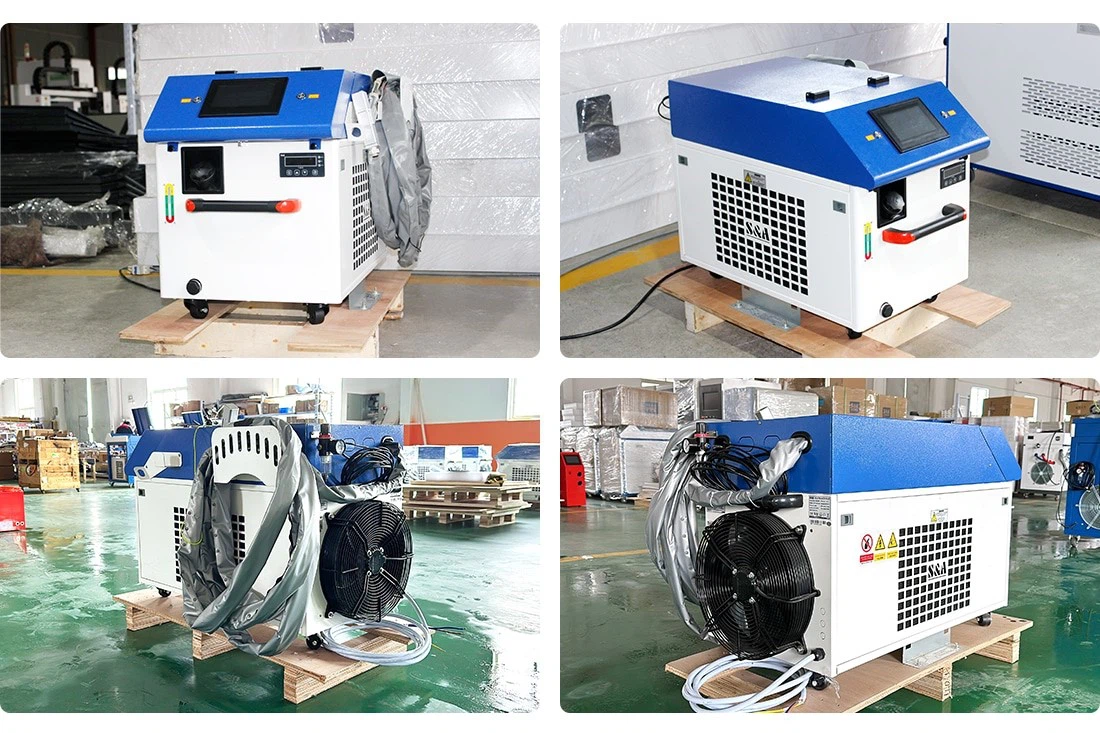

Machine size: 940*550*680mm

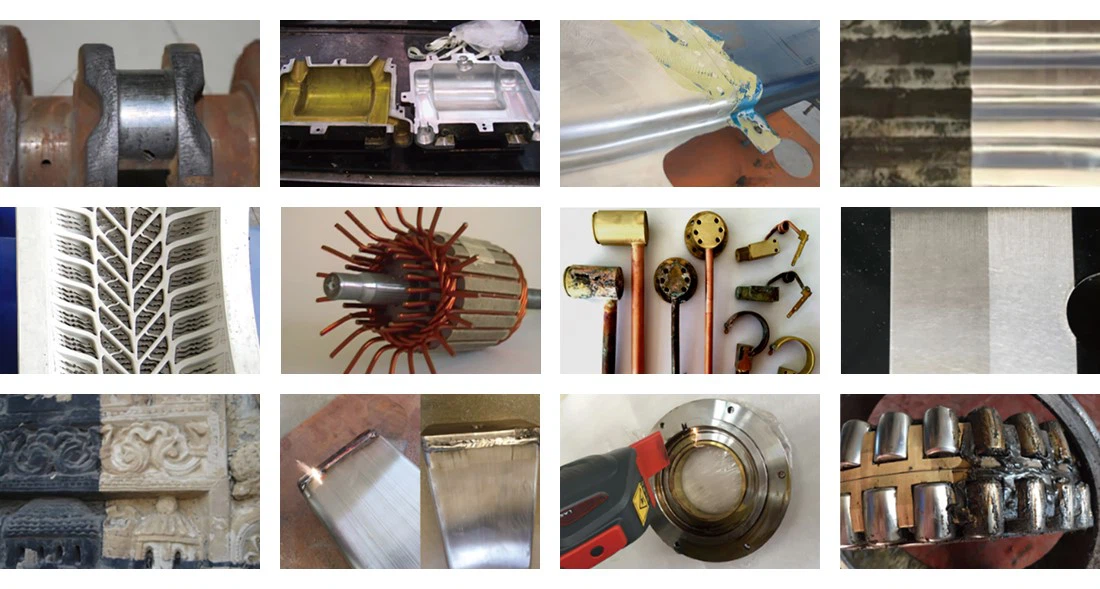

Oxide layer removal/Grease removal/Paint removal/Rust removal

The laser cleaning machine is a cutting-edge device that harmesses the power of laser technology to perform surface cleaning and remove coatings. Its versatile applications span across a multitude of industries, including industrial manufacturing, automotive maintenance, cultural heritage preservation, and beyond.

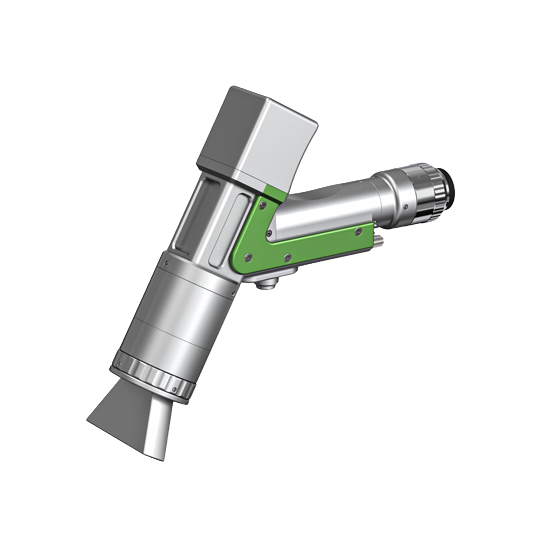

Support Relfar, Super chaoqiang, Qilin Au3Tech different brands of cleaning head.

Safety - Temperature real-time monitoring

Time saving- Easy replacement lens

Lightness -Small size, easy to use and simply to operate

Stable -Upgrade to dual protective lenses.

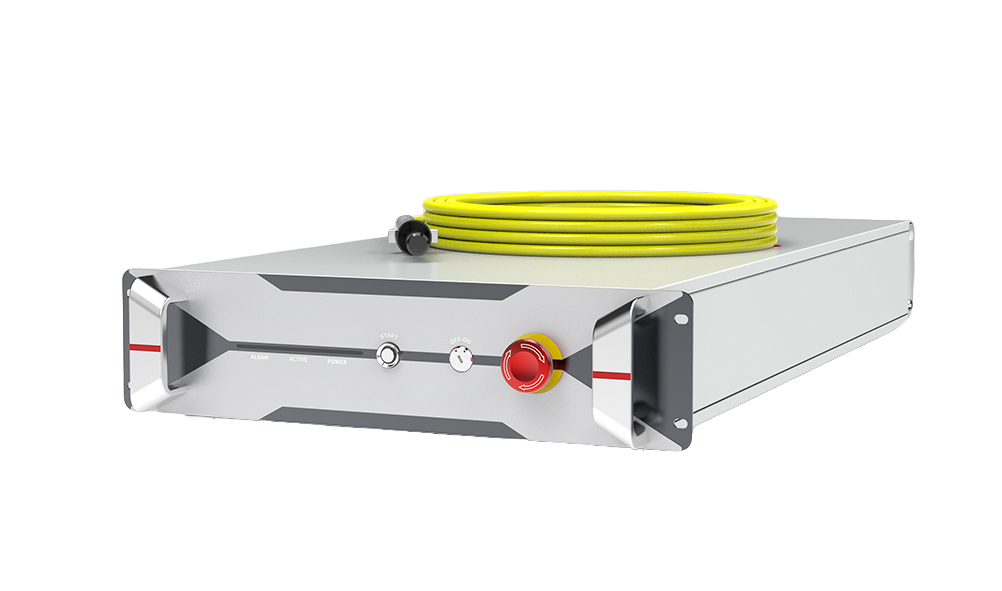

The  optional brands of fiber lasers include Raycus, RECI, GW, FEIBO, IPG, and MAX. Photoelectric conversion rate exceeds 50%, energy-saving and environmentally friendly. Working life is100, 000 hours.

The intelligent temperature controller of the laser chiller has two temperature control modes, suitable for different usage scenarios; There are multiple settings and fault display functions; The temperature control accuracy can reach ± 0.5 ℃; Stable refrigeration and easy operation;

As an advanced cleaning technology, fiber laser cleaning machine is widely used in many industries: automobile manufacturing industry, aerospace, electronic and electrical appliances, precision instruments, shipbuilding, mold manufacturing and other industries.

Whether metal, non-metal or composite materials, it can provide the right cleaning solution. For metal materials, laser cleaning can remove surface oxides, oil and coatings; For non-metallic materials such as glass, ceramics and plastics, it can remove surface stains and scratches; For composite materials, laser cleaning can ensure that the cleaning effect is consistent between different materials and avoid damage to the substrate.

| Laser power | 1000w | 1500w | 2000w |

| Central Wavelength | 1080nm | ||

| Laser Running Mode | Continuous Mode | ||

| 10-20KHzFrequency | 10-20KHz | ||

| Fiber Cable Length | 8m | ||

| Cooling Type | Water Cooling | ||

| Scanning Width | Max 300mm | ||

| Voltage | Single phase 220V,50/60Hz | Three phaser 380V.50/60Hz | |

| Total Consumption | 5.5KW | 8KW | 13.5KW |

| Beam width | ≤200mm | ≤200mm | ≤300mm |

| Rust | 20㎡/h | 40㎡/h | 60㎡/h |

| Oil | 8㎡/h | 12㎡/h | 16㎡/h |

| Paint | 8㎡/h | 12㎡/h | 16㎡/h |

01Non-Contact Cleaning:

Laser cleaning operates without physical contact, preventing wear and tear during the cleaning process. This feature is especially advantageous for maintaining high precision on the object's surface.

02High Precision and Control:

Laser beam focus is meticulously controlled, enabling the targeted removal of contaminants from specific areas while leaving surrounding regions unaffected.

03Chemical-Free Process:

Laser cleaning is a purely physical method, eliminating the need for chemical solvents or cleaning agents. This not only avoids chemical pollution but also sidesteps concerns related to waste disposal.

04Energy-Efficiency and Environmental Friendliness:

Laser cleaning typically consumes less energy compared to traditional methods, and it generates minimal wastewater or exhaust gases, aligning with eco-friendly practices.

05Versatility Across Materials:

Laser cleaning's applications span various materials, showcasing remarkable adaptability.

Xianming Laser Co., Ltd. is an international and intelligent laser machinery manufacturer. Our main products including fiber laser cutting machine, fiber laser welding machine, CO2 laser engraving machine, laser marking machine, cleaning machine, and other laser equipments. We have launched over 60 types of laser products, covering applications in various industries such as automotive, aerospace, medical, metalworking, and electronics.Can satisfy different production needs of customers.

All our machines obtained international certifications such as CE, Rohs,and FCC. Our products have been sold to multiple countries such as the United States, Mexico, Australia,Canada,Brazil,Switzerland and have won unanimous praise from domestic and foreign users.

We also welcome OEM and ODM orders. Whether selecting from our current models in the catalog or seeking engineering assistance for your application, you can contact our customer service center regarding your procurement requirements.

01. What is the speed of the laser cleaning machine?

Different laser types determine the cleaning speed of the cleaning machine, and the cleaning speed iswithin the range of 0.5m2/h-15m?/h.

02. Is there any damage to the cleaning material?

Depends on what type you need, the pulse type has a finer cleaning effect, and the continuous type hasa faster cleaning speed,Relative damage of material, pulse type is less than continuous type.

03. What are consumable parts?

Protective glass, etc, if you order, we will send it to you together with machine.

04. Which languages are supported? Is it easy to operate?

Support language: Chinese, English, Korean, Russian, Chinese Traditional, Japanese, German, French.ltalian, Spanish, Portuguese, Turkish, Greek, Czech Slovak, Polish, Thai, Vietnamese, Romanian, etc,with clearand simple interface page Stable Various parameters can be set by yourself

05. When I get the machine, how to operate the machine?

We have user manuals and video tutorials, and this machine is very easy to use. You will soon learn howto use it.

06. ls the laser cleaning machine safe? What are the hazards to human health?

The laser cleaning machine is generally safe when used and operated correctly following safety guide.lines. However, it is essential to adhere to our instructions for implementing electri

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy policy

- Blog