Máy cắt laser sợi kim loại là một sản phẩm tuyệt vời, chắc chắn rồi, vì nó cải thiện và hoàn thiện quy trình cắt kim loại tấm mỏng theo nhiều cách. Một máy laser đã đưa công việc chế tạo kim loại vào một kỷ nguyên mới của sự chính xác và tốc độ. Máy cắt laser sợi kim loại này trở thành sự cứu rỗi công nghệ và đã biến đổi toàn bộ quá trình sản xuất, đặc biệt là ở những lĩnh vực có sự tồn tại của việc làm việc với kim loại tái sử dụng, chẳng hạn như đóng tàu, sản xuất ô tô, hàng không vũ trụ và xây dựng. Và nó không chỉ cách mạng hóa máy cắt laser sợi kim loại duy nhất, mà còn tái cấu trúc hầu hết mọi phần của quy trình gia công. Dòng nước áp suất siêu cao đã được sử dụng lâu nay để cắt thép trong ngành công nghiệp kim loại, cũng như để cắt các kim loại chính như thép không gỉ, nhôm, đồng thau và đồng. Sau khi tích hợp máy cắt laser sợi, không cần đến hệ thống thủ công nữa và nó tiết kiệm chi phí và thời gian cho quá trình gia công kim loại. Không có giới hạn nào đối với người vận hành máy cắt laser sợi, trong khi trong quá trình cắt kim loại, công nghệ laser sợi mang lại mức độ chính xác và tốc độ chưa từng có. Nó tăng cường khả năng xử lý các khu vực và hình dạng mà không có lỗi nhờ vào tia laser tập trung. Tốc độ laser được sử dụng trong máy cắt laser sợi nhanh hơn so với các loại khác, và nó cắt kim loại dày nhanh chóng và hiệu quả hơn. Máy cắt laser sợi đang cách mạng hóa cách ngành công nghiệp chế tạo kim loại hoạt động theo nhiều cách. Một lĩnh vực mà hệ thống DMLS đã nâng cao đáng kể quy trình sản xuất là sản xuất nhanh chóng và chính xác hơn các linh kiện kim loại. Máy cắt laser sợi cũng đã giảm nhu cầu hàn thạch cao; các nhà sản xuất đã tiết kiệm hàng chục giờ công lao động và chi phí. Sản xuất bền vững kim loại phát triển thông qua công nghệ laser sợi. Các nhà sản xuất tiết kiệm thời gian khi sản xuất các linh kiện kim loại chất lượng cao do khả năng cắt nhanh qua nhiều loại kim loại như dự đoán. Ngoài ra còn có sự tiết kiệm chi phí nhân công tốt hơn trong quá trình gia công kim loại. Các hoạt động cắt của máy cắt laser sợi tạo ra ít chất thải hơn, do đó tăng tính bền vững của hoạt động. Vì vậy, nếu bạn muốn có một mảnh kim loại từ máy cắt laser sợi, thì đó là một lựa chọn lý tưởng. Đây là một sản phẩm cực kỳ tuyệt vời, mang lại thay đổi mạnh mẽ cho ngành công nghiệp này. Việc cắt kim loại đã trở nên nhanh chóng và chính xác hơn rất nhiều, điều này đã được chứng minh bởi khả năng về tốc độ và độ chính xác của nó. Nó đã chứng tỏ là vô cùng quan trọng trong các lĩnh vực như đóng tàu, sản xuất ô tô, hàng không vũ trụ và xây dựng.

Và sự tiến bộ không chỉ giới hạn ở một máy cắt laser sợi duy nhất, mà nó đã cải tiến hầu hết mọi yếu tố của quá trình gia công. Trước đây, các nhà sản xuất đã sử dụng nước để cắt thép dưới áp suất cực cao, cũng như cắt nhiều loại kim loại khác nhau bao gồm inox, nhôm, đồng thau và đồng. Đây là sự tích hợp của máy cắt laser sợi, đã hoàn toàn loại bỏ nhu cầu hệ thống thủ công và tiết kiệm thời gian, chi phí trong quá trình gia công kim loại.

Chỉ có giới hạn những gì người vận hành có thể làm, nhưng công nghệ laser sợi mang đến độ chính xác và tốc độ chưa từng có trong các hoạt động cắt kim loại. Với máy cắt laser sợi, việc xử lý các hình dạng phức tạp trở nên dễ dàng hơn mà không có lỗi nhờ tia laser tập trung. Ngoài ra, tốc độ của laser được sử dụng trong máy cắt laser sợi nhanh hơn, giúp cắt kim loại dày một cách nhanh chóng và hiệu quả.

Theo nhiều cách, máy cắt laser sợi đang thúc đẩy một sự thay đổi lớn trong cách ngành công nghiệp chế tạo kim loại hoạt động. Tốc độ và độ chính xác cao hơn trong việc sản xuất các bộ phận kim loại là một lĩnh vực chính mà hệ thống DMLS đã cải thiện đáng kể. Việc tạo ra các quy trình ít tốn công lao động hơn cũng đã giúp tiết kiệm thời gian và tiền bạc trong việc gia công kim loại. Cuối cùng, việc giảm thiểu chất thải vật liệu liên quan đến máy cắt laser sợi giúp quá trình gia công kim loại trở nên bền vững hơn.

Công nghệ laser sợi đã cải thiện đáng kể hiệu quả và tính bền vững của việc gia công kim loại, cách mạng hóa cách thức thực hiện. Các nhà sản xuất rút ngắn thời gian tạo ra các bộ phận kim loại bằng cách cắt qua nhiều loại kim loại một cách nhanh chóng và như mong đợi. Sự giảm nhu cầu về lao động thủ công cũng tương ứng với chi phí nhân công tốt hơn. Máy cắt laser sợi tạo ra ít chất thải hơn so với các hoạt động gia công kim loại truyền thống, cho phép thực hành một cách bền vững hơn.

Tóm lại, nếu bạn muốn có một phần của máy cắt laser sợi như là một sản phẩm tuyệt vời, điều đó đã thay đổi ngành công nghiệp này một cách mạnh mẽ. Nó đã khiến quy trình cắt kim loại trở nên nhanh hơn, chính xác và tinh tế hơn nhờ khả năng độ chính xác và tốc độ tuyệt vời của mình. Máy cắt laser sợi đã chứng minh rằng chúng là yếu tố không thể thiếu trong các ngành công nghiệp như đóng tàu, sản xuất ô tô, hàng không vũ trụ và xây dựng bằng cách tối ưu hóa hoạt động và giảm thiểu lãng phí.

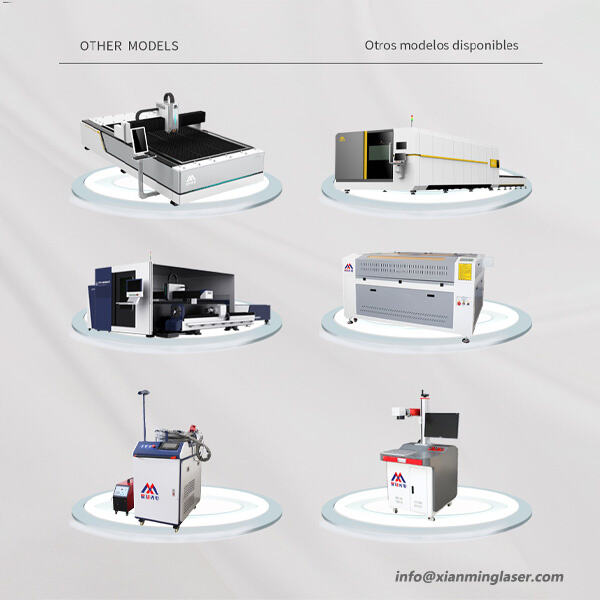

Liaocheng Xianming có một đơn vị sản xuất rộng 30000m vuông. Chúng tôi sở hữu bộ phận nghiên cứu và phát triển hàng đầu trong ngành, vì vậy chúng tôi tập trung vào việc tạo ra nhiều loại máy laser sợi khác nhau.

Liaocheng Xianming sản xuất cho khách hàng với logo cá nhân hóa cùng video, hình ảnh và các tài liệu khác. Các đại lý cũng cung cấp các mặt hàng tùy chỉnh theo yêu cầu của khách hàng. Máy cắt laser sợi quang của chúng tôi có xu hướng tiên tiến hơn so với nhiều nhà sản xuất khác, các dịch vụ và sản phẩm chính của chúng tôi bao gồm một loạt máy cắt kim loại laser công suất cao, máy hàn laser, máy làm sạch và máy khắc CO2, máy đánh dấu.

Liaocheng Xianming Machines cung cấp bao bì vận chuyển chuyên nghiệp để mang lại dịch vụ vận chuyển nhanh chóng và hiệu quả cho khách hàng, giúp giảm chi phí logistics. Chúng tôi sẽ cố gắng hết sức để đảm bảo rằng máy laser sợi đến đích nhanh chóng và đúng cách, bất kể bạn là cá nhân hay doanh nghiệp.

Liaocheng Xianming rất chú trọng đến dịch vụ sau bán hàng, biết rằng dịch vụ tốt đối với máy cắt laser sợi quang là điều vô cùng quan trọng. Chúng tôi tuân thủ các nguyên tắc lấy khách hàng làm trung tâm và có mặt toàn cầu. Điều này được thực hiện thông qua sự hỗ trợ từ mạng lưới dịch vụ.

Bản quyền © Công ty TNHH Xianming Laser Liaocheng. Tất cả các quyền được bảo lưu. - Chính sách bảo mật- Không.Blog