У таких умовах, відомо, що відкриття певного сучасного та високотехнологічного продукту - CNC металевих фібр лазерних різаків стає поширене серед всіх, про це говорять на вулицях. Вдома, а також у комерційних застосуваннях, які включають багато видів продукції, тепер потрібні виробничі роботи, автомобілебудування, коледжі та університети, наукові установи, здається, лише літаки встановлюють строгі вимоги до ефективності. Ці інструменти буквально змінили виробничу галузь і створили її заново. На даний момент ми продовжимо нашу дискусію, щоб виявити більше переваг, а також недоліків, прибутку та менш складного виробництва за допомогою металевих фібр лазерних різаків.

Виникає питання, чому багато підприємств, зокрема в галузі металів, пластиків тощо, використовують CNC лазерні різальні машини. Одна з найзначніших їх характеристик полягає в тому, що вони забезпечують високоточні результати, що є ключовою причиною, чому компанії використовують їх для виробництва або будівельних застосувань. Ці машини працюють швидше і продуктивніше, ніж сучасний ручний труд людини. Лазерний промінь може перерізати навіть найгrubшi листи металу, досягаючи швидкості та точності, якої раніше не було. Це пов'язано з тим, що тривалість стану подібного газу дуже коротка. Крім того, оскільки ці машини керуються комп'ютерною системою, вони дуже автоматизовані, що мінімізує шанс на помилку через людський фактор. У галузях, таких як авіакосмічна, автомобільна та медична інструментальна, де точність і точність грають важливу роль, така автоматизація є корисною.

Щодо продуктивності, немає іншого рішення, яке могло б забезпечити кращі результати, ніж машини для розрізання металу за допомогою лазера з волоконною оптикою CNC. За дуже короткий час вони можуть стати найкращим рішенням, замінюючи традиційне розрізування, свердлення та гравірування. Вони здатні виконувати операції, такі як розрізування металевих пластин, завдання, яке іншим машинам потрібно години замість кількох секунд. Недавно було зафіксовано значний зменшення часу обробки в промислових підприємствах, таких як авіакосмічна та автомобільна галузь, коли використовуються інструменти, такі як машини для розрізання металу за допомогою лазера з волоконною оптикою CNC, щоб значно зменшити витрати. Складні деталі та компоненти тепер можна виготовляти швидше, ніж раніше, що дозволяє проводити прототипування та тестування на всіх етапах розробки.

Станки з лазерної різки металевих волокон на основі CNC можуть виконувати ультraprecизні, високоякісні розрізи в багатьох матеріалах, таких як метали, пластики та композити тощо. Але саме мalleабільність у дизайні, де складність і деталізація можуть бути включені в моделі, робить їх унікальними від інших пристроїв. Крім того, програмування CNC вилучає обмеження і дозволяє завершити проекти за досить короткий період (9). Станки з лазерної різки металевих волокон CNC насправді схожі на надздатність і змінили спосіб виготовлення речей. Упрощення процесу виготовлення Cnc Metal Fiber Laser Cutting Machine

Станок з лазерної різки волоконного типу CNC та заміна людської праці. З появою інструментів для плазменого гравювання на основі CNC відбулася радикальна зміна у тому, як ми проводили наші виробничі процеси. Програмування CNC дозволяє не тільки створювати предмет, але й редагувати й закінчувати його. Після цього станок CNC може забрати на себе все при мінімальному або відсутньому обслуговуванні поза отриманням початкового дизайну. Раніше виробничий процес залежав від досвіду оператора, його здібностей та регулярного контролю. Проте, волоконні лазерні різальні машини CNC з металу не потребують людського нагляду для роботи (11). Зміни у виробничих процесах завдяки машині CNC з волоконним лазером для різки металу

Це призвело до покращення виробництва завдяки їхній технології, тому ефективність виробництва деталей та створення відходів зменшилася. Тепер справи стають навіть складнішими, а кількість продукції, яку можна виготовити, чиїй бути призначення для авіакосмічної галузі чи автомобілів, пристроїв чи медичних технологій, продовжують рости. Наслідком є кращі готові продукти, створені швидше, ніж колись раніше. Крім того, CNC лазерна машина може використовуватися для виготовлення предметів, які раніше не мали бути виготовлені (наприклад: індивідуальна більоння, трофей чи плакети), і тепер це просто й швидко (14).

У короткому, CNC-машини лазерної різки металевих волокон технічно є активом, який зробив виробництво простішим завдяки економії часу та енергії, одночасно покращуючи якість продукції. Наприклад, ці точні машини можуть створювати деталізовані дизайни, які неможливо виконати вручну без автоматизації для виробників, досягаючи непорівнянної точності та досконалості. Як результат постійного удосконалення інструментів автоматизації та рівнів стандартизації за допомогою штучного інтелекту - сьогодні на чолі з CNC-машинами лазерної різки металевих волокон, ми йдемо до ери, коли багато наших сподівань щодо покращення виробництва може легко стати дійсністю.

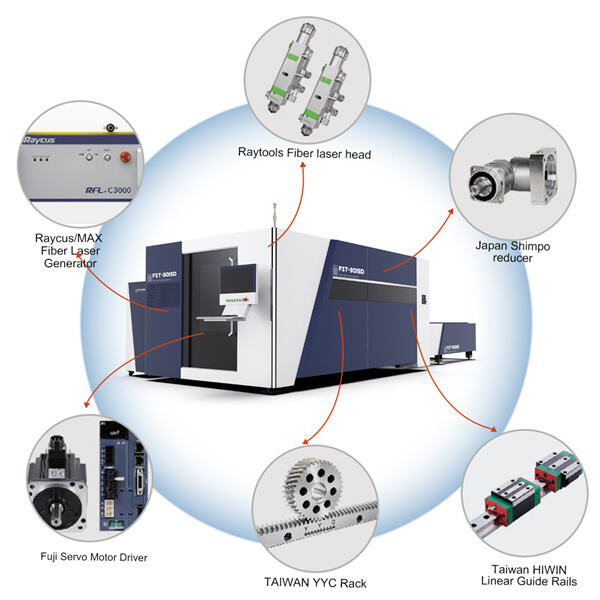

Ліаоченг Сянмінг займає площу 30000 квадратних метрів на заводі, продається із відмінною командою у галузі, окрім того, спеціалізується на створенні та розвитку різноманітних видів волоконних лазерів. У нас багато патентів технічного характеру, ми вже отримали сертифікацію якості ISO9001, а також євро сертифікацію CE та сертифікацію FDA.

Liaocheng Xianming може надавати клієнтам логотипи та інші персоналізовані послуги, включаючи агентів з зображеннями для логотипу клієнта, продукту, відео та інших предметів. Наша волоконна лазерна машина має вищу якість, ніж у інших постачальників. Головний наш товар — це широкий асортимент високоможливих металевих лазерних різальних машин, лазерної сварочної машини, чистячої машини, а також машини CO2 для гравюрування та маркування.

Ринок та спільнота продажів машин Liaocheng Xianming охоплюють більше 60 країн та регіонів. Це дуже ефективна процедура логістичного упаковування, яка забезпечує швидку доставку вашим клієнтам, щоб логістика ставала простішою. Неважливо, чи є ви користувачем або компанією, ми робимо все можливе, щоб задовольняти ваші потреби та доставляти фіберний лазерний станок туди, куди потрібно, безпечно і швидко.

Ляоченг Сянмінг приділяє багато уваги послугам після продажу, розуміючи, що якісна служба та якісні волоконні лазерні машини є однаково важливими. Ми дотримуємося принципів клієнт-орієнтованості, глобального присутнього покриття, підвищених послуг мережевої підтримки та 24-годинної онлайн-послуги. Ми будемо зусиллями пропонувати нашим клієнтам високоякісні продукти та сервіс.

Авторське право © Компанія Liaocheng Xianming Laser Co., Ltd. Всі права захищені. - Політика конфіденційності-Блог