Uvedené vyššie je rozdelené na niekoľko bodov, nasledujúci obsah tohto článku bude založený na týchto špecifickych prvkoch pre rozklad a hlbokú analýzu stroja na rezači listového kovu pomocou fiberoptického laseru! Tento úžasný stroj je vyrobený špeciálne na rezanie rôznych druhov listového kovu, rýchlo a plynulo. Okrem rezania kovu s vysokou úrovňou presnosti vyvíja rôzne tvarové a veľkosti, ktoré môžu slúžiť mnohým rôznym účelom.

Fiberoptické laserové rezanie používa vysoko intenzívny dynamicky usmerňovaný fiberoptický laserový papier na rezanie kovu. Hrubý alebo tenký list, tento stroj ho dokáže vyrezať s najglatejším dokončením a bezposchopným koncom, ktorý sa dá očakávať len od neporovnateľnej presnosti. Schopnosť nástroja vykonávať detailné rezy s presnosťou je ideálna pre rôzne potreby rezania kovu.

Výhody používania stroja na rezačnú fibrovú laserovú rezbu plechu. Môžete orezať čokoľvek v zlomku času, takže sú rovnako prивлекаtractive pre väčšie projekty, kde je dôležitá rýchlosť rezu. Druža, pruči flexibilný stroj môže rezať cez rôzne typy kovových povrchov ako je nerdzavé oceli, hliník a miedz v krátkej dobe, čo ho ne len robí ideálnym pre vás, ale tiež zabezpečuje mnoho univerzalných možností pri práci na rozdielnych spájacie projekty. Laserový paprsek je tiež veľmi zameraný, aby sa minimalizoval poškodenie a deformácia plechu spôsobené teplou.

Prispevok od LAS SouthAko laserová technológia podporuje výrobu plechových konštrukcií na plné kolo - Fibrová laserová rezačná stroj, cleveland.

Proces výroby plechových komponentov sa skladá z rôznych tvarov, ktoré sú vyformované z týchto materiálov do požadovaných foriem a tiež veľkostí. Odraz v plechovej výrobe je rovnako často používaný a umožňuje vyrábať mnoho položiek pomocou riadeného procesu vykonaného na týchto oceľových produktoch. Stroj na rezanie plechu fibrovým laserom úplne premenil tento výrobný proces, pričom významne zvýšil pracovnú efektivitu a znížil náklady. Metóda výroby plechových komponentov bola experimentovaná s fibrovým laserovým rezačom, a v dôsledku tohto systému, ktorý funguje s takou imponujúcou efektívnosťou, bolo dosiahnuté nové hladiny výroby.

Keď ide o priemysel výroby plechov, nemôžeme sa pozbyť štandardného vybavenia – kapacity na rezačnú fibrovú laserovú technológiu. WeRib][2] je správne k vašim službám! Bolo to hlavnou charakteristikou pri výrobe mnohých produktov a štruktúr, čo mu umožňuje byť používané tam, kde je potreba nejakých sestavovaných častí. Tento stroj sa stal dôležitým pridáním v dnešných výrobných priemysloch kvôli svojej schopnosti rezať cez rôzne kovy s presnosťou, presnosťou a v úžasnej rýchlosti.

Stručne povedané, stroj na rezači laserom z vlákien je podvrtným zařadením na spracovanie plechu. Proces umožňuje moderný pokrok v výrobe kovu, ktorý dokáže efektívne a presne rezať prakticky akýkoľvek druh kovu, pomáha vyrobiť produkty lacnejšie ako pri použití tradičných rezačných procesov alebo poskytuje vyššiu kvalitu konečného sústavy - a architektonických častí. Každá z komponentov stroja na rezači vlákneného laserom pre plechy pracuje s presnosťou, ktorá je takmer zázračná.

Stroj na režanie laserom s vláknom používa sílu dynamického laserového paprsku vodicova vláknom na rozdelenie kovu. Bez ohľadu na hrúbku listu, či už silného alebo tenkého, tento stroj Vám ponúka hladký dokončený výsledok s nezrovnateľnou presnosťou. Jeho schopnosť vykonávať komplikované rezy, zatiaľ čo udržiava presnosť, robí z neho ideálny nástroj pre rôzne druhy kovového reza.

Výhody používania stroja na rezači listového kovu laserom s vláknovým laserom sú naozaj niečo úžasné. Jednou z výhod je, že je neuväřiteľne efektívny a môžete rezať niečo za zlomok času, čo ich robí veľmi atraktívnymi pre väčšie projekty, kde je čas na rezy kritický. Druhou vecou je, že tento prispôsobivý stroj môže rýchlo prerezávať rôzne typy kovových povrchov, ako je tvrdená ocel, hliník a miedz, čo ho robí ideálnym pre vás a zaručuje, že vaše možnosti sú nekonečné pri rozvažovaní rôznych svárnicích projektov na prácu. Nakoniec je lúčový paprsek vysoce koncentrovaný, aby sa minimalizoval poškodenie a deformácia kovového listu spôsobené teplou.

Postup premeny plechových listov na rôzne tvar a veľkosti sa nazýva výroba plechových listov. Šírka: Výroba plechového ocele sa používa na rôzne priemyselné účely a umožňuje vytvárať rôzne produkty cez riadený proces vykonaný na týchto ocelových materiáloch. Príchod stroja na rezu plechových listov pomocou vlákenného laseru transformoval tento výrobný proces, čím zvýšil efektivitu a ušetril náklady. Metóda výroby plechových listov bola zdokonalená pomocou technológie vlákenného laserového rezu a tento laserový systém pracuje s najvyššou efektivitou, akú kedy bolo vytvorené.

Keď hovoríme o priemysle výroby plechových konštrukcií, nemôžeme nezabudnúť na jednu kľúčovú zariadenie – stroj na rezu fiberoptickým laserom pre plechy. Pomohol pri výrobe mnohých produktov a stavení, ktoré by neboli možné bez tejto schopnosti tvarovať jednoduché roviny kovového plechu do zložitých foriem. S kapacitou reza cez mnoho kovov s presnosťou, nespresnosťou a rýchlosťou sa tento stroj stal kritickou pridávkou v dnešných modernejších výrobných odvetviach.

Záverom môžeme povedať, že stroj na rezači vlasového laseru je revolučným zariadením v oblasti obrábania plechu. Jeho vznik premienil výrobu kovových konštrukcií schopnosťou rezať prakticky akúkoľvek druh kovu efektívne a presne, čo viedlo k vyššej produktnosti, nižším výrobným nákladom v porovnaní s tradičnými rezačnými procesmi a umožňuje tvoriť komplexné geometrie, ktoré sú srdcom mnohých komponentov/produktov/stavieb. Presnosť, s akou každá časť stroja na rezači vlasového laseru pre plechy funguje, je nielen čudomocná.

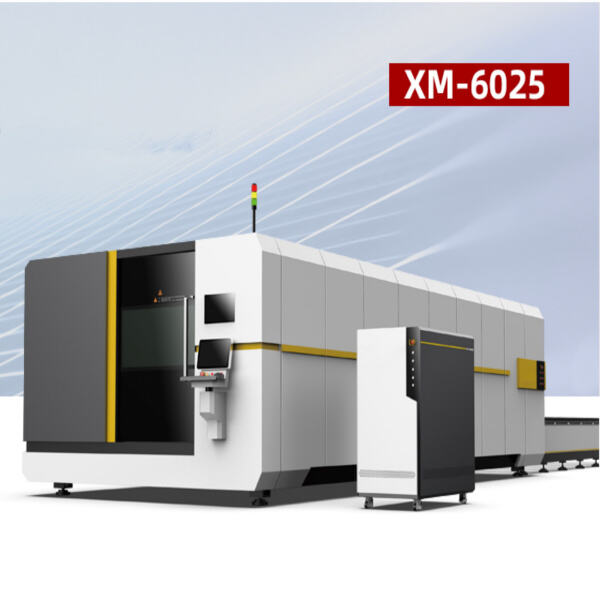

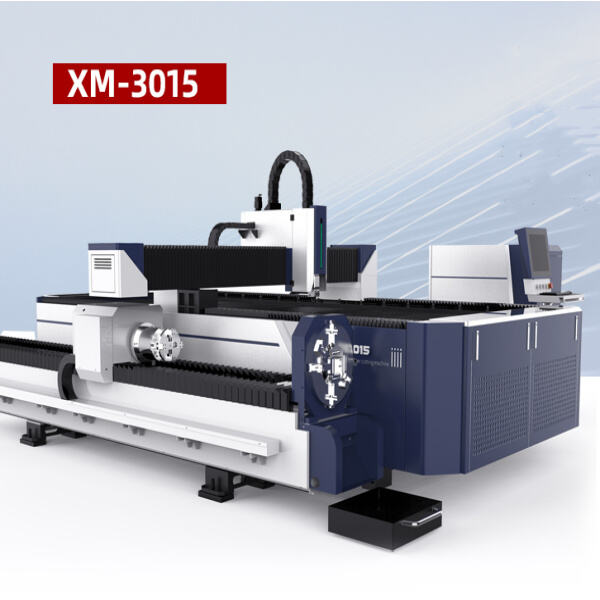

Liaocheng Xianming sa intenzívne sústreďuje na predaj po dodaniach, vedie, že dobrá obsluha po predaji a vysokokvalitné fibrové lasery sú pre nás rovnako dôležité, drží sa princípov zhody so svetom, orientovaného na zákazníkov prítomnosť, ktorá sa zvyšuje prostredníctvom siete podpory služieb a bude 24 hodín online služba, snaží sa maximálne poskytovať zákazníkom lepšie produkty a lepšiu službu.

Liaocheng Xianming poskytuje zákazníkom personalizované logo a videá, grafiku a materiály. Zástupci môžu tiež ponúkať produkty s označením zákazníka. Fiber Laser stroje sú lepšie ako produkty iných výrobcov.

Liaocheng Xianming zahŕňa 30000 štvorcových metrov továrne a má teraz vrcholný tím R&D na trhu, ktorý sa zaoberá rastom a výrobou rôznych typov vlknatých laserov. Majúme veľké množstvo technických patentov a dosiahli sme systém certifikácie kvality IS09001, európsky certifikát CE a certifikát FDA.

Spoločnosť Liaocheng Xianming Machines ponúka profesionálnu baliciu logistiku vybudovanú na poskytovanie rýchlych dopravných služieb pre zákazníkov a uľahčenie logistiky. Pokúsime sa zabezpečiť, aby vaša fibrová Laserová strojnícka jednotka dospela do destinácie rýchlo a bezpečne, nezávisle na tom, či ste spoločnosť alebo jednotlivec.

Všetky práva vyhradené pre Liaocheng Xianming Laser Co., Ltd. - Zásady ochrany súkromia-Blog