Plāksnēm Metalu Laser Griešanas Ierīces

Lazeru griešanas mašīnas ir spēlējušas galveno lomu ražošanas nozarē, ieviešot daudzus novatoriskus uzlabojumus pēc lasera tehnoloģijas. Lietmetālu plāksnēm paredzētie lazeru griešanas aparāti ir speciāli izstrādāti, lai padarītu darbu unikālu un tikpat kā neatņemamu plāksnēm griešanas procesu. To ātrums un precizitāte ir mainījusi to, kā notiek metāla griešana kā process, padarot to ražošanā ātrāku, samazinot materiāla zudu un radot ļoti precīzas griešanas vietas.

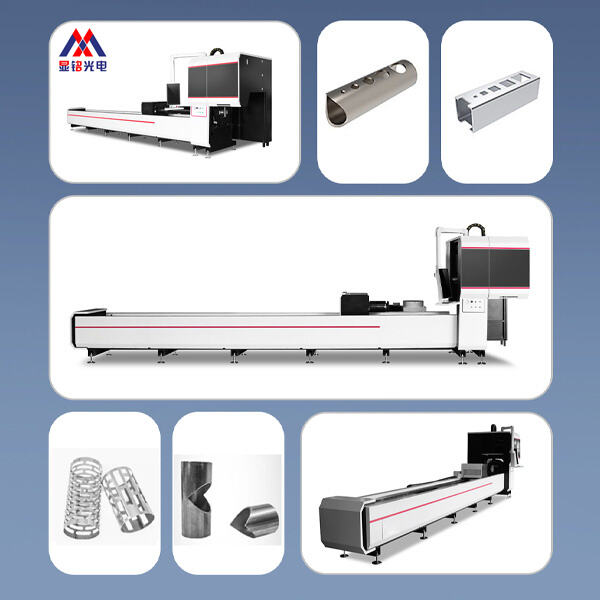

Tirgū, pirkt nolūkā lietojamo lazeru griešanas mašīnu, jūs varat sastapt daudz iespēju. Tas var būt grūti noteikt pareizo variantu, jo šis posms ir diezgan nozīmīgs. Šeit mēs iepazīstinām ar piecu labāko lazeru griešanas mašīnu modeliem, kas paredzēti lietmetālu plāksnēm 2021. gadā, lai palīdzētu jums ar izvēli. Turklāt mēs runāsim par to, kā fiber lasera tehnoloģija plāksnēm griešanai sniedz papildu priekšrocības.

Palielināta lietmetālu plāksnēm paredzēto lazeru griešanas produktivitāte

Ātrums - Lazeru griešanas mašīnu izmantošanas nozīmīgs priekšrocības ir tas, ka tās spēj griezt materiālus ļoti ātri, vienlaikus nodrošinot augstas kvalitātes izvadi. Šī ātra efektivitāte ir liela vērtība plāksnēmetālu tirgū, jo tā ļauj ražotājiem paaugstināt savu produktivitāti, ražojot vēl vairāk produktu daudz īsākā laikā. Galu galā tas rezultē uzlabotā peļņā uzņēmumiem.

Lazeru mašīnu noderība plāksnēmetālu izgatavošanā

Lazeru griešanas mašīnas piedāvā lielu daudzveidību un spēj griezt daudzus materiālus, tostarp nerīdzo celso, aluminiju vai oglekļa celso un citus. Tās strādā tā, lai veiktu precīzas griešanas un nodrošinātu galīgā produkta pareizu darbību. Lazeru mašīnu ietekme uz plāksnēmetālu izgatavošanu ir imensa; tā ir optimizējusi ražošanas procesu un uzlaboja izvades kvalitāti; ne minējot arī uzņēmumu peļņas pieaugumu.

2021. gadā, | Labākais plāksnēmetālu jomā: TOP 5 lasera griešanas mašīnas

Tas ir straujais un ļoti spēcīgais, griezdams lielas dales dēļ augstas uzvedības. Tas ir visvairāk piemērots lielam un sarežģītam projektam dēļ lietotāja draudzīgas saskarnes.

Viens no stiprākajiem rīkiem, kas viegli griež cauri smagiem materiāliem, ir augstspeca palīdzības gāzes sistēma. Turklāt augstas ātruma šūtu galda izmantošana ir samazinājusi ražošanas laiku.

Moderns arī tehnoloģijām, kas balstās uz moderno šķiedras laseru tehnoloģiju precīzu griešanu. Šis enerģijas taupīgais dizains nolasa samazināt uzņēmumu darbības izmaksas.

Ātrums: 5000 mm/minūtē (197 colīm/minūtē) Materiāli Storibordi Froms Kārtceļi Dzelme Apgabali Magnētiskais papīrs Augstas apjoma ražošana līdz 0,75 colas faktiskais materiāla biežums. Tas ir geniāls starojuma kontroles sistēmas, kas nodrošina neatņemamu precīzu griešanu.

Prima Power Laser Genius

Uzlabota mašīna, kas var griezt daudzas dažādas materiālu veidus ar augstu precizitāti. Tajā ir arī lietotāja draudzīgs saskarnis vieglai izmantošanai un tā strādā labi ar sarežģītiem projektiem.

Kāpēc vērts apsvērt fibrogaisma tehnoloģiju jūsu plāksnēmets griešanai?

Pēdējo desmit gadu laikā fibrogaisma tehnoloģija ir kļuvusi par parastu plāksnēmets fabrikācijā, jo tai ir daudz priekšrocību salīdzinājumā ar tradicionālo CO2 bāzēto gaisma. Šīs priekšrocības ietver ražošanas ātrumu, griešanas kvalitāti ar minimālu atkritu materiālu ražošanu procesā salīdzinājumā ar tradicionālajām griešanas metode, kurām nepieciešama termiskā enerģija, lai zīmētu/grieztu un sadalītu plāksnes; samazināts naudas maksājums par katru plāksni, taupot vismaz daļu no elektroenerģijas rēķina, jo dienu pārstrādājamās stundas ir mazākas; iespējams nogriezt jaunas pamateriālu šķautnes, kas agrāk bija pārāk grūtas vai neiespējamas.

Kā izvēlēties pareizo laser griešanas mašīnu

Izvēle pareizā lasera griešanas mašīnai jūsu uzņēmumam atkarīga no tā, kas jums nepieciešams darīt, un parametri, kas noteikti šajos punktos. Uzņēmumiem, kuri vēlas veikt augstas kvalitātes griešanu uz tumšiem materiāliem, CO2 lasers būs izvēles instruments. Tiesotājiem, kas meklē ātru caurstrādi kopā ar daudz vairāk elastību noteiktās robežās un arī citiem aspektiem, der fiber lasers. Kopsavilkumā lasera griešanas mašīnu inovācijas ir automatizējušas plāksnēm metalu ražošanas procesu, samazinot ražošanas laiku līdz minimumam un palielinot kvalitātes standartus paralēli ar darbības efektivitātes pieaugumu. Faktori, piemēram, ražošanas apjoms, materiāla tips un precizitātes līmenis, kas nepieciešams, lai procesētu ideālus daļiņas, jāapsver, lai mašīna būtu piemērota jūsu uzņēmumam.

Liaocheng Xianming nodrošina klientiem pielāgotus logotipus un attēlus, video kopā ar citiem materiāliem. Aģenti bieži var piedāvāt brīdinājumus par preču marķieri no klientiem. Fibro laser mašīna ir daudz labāka nekā vairums citu sniedzēju.

Liaocheng Xianming mašīnu tirgus un pārdošanas kopiena ietver vairāk nekā 60 valstis un reģionus. Tas ir ļoti efektīvs loģistikas un pakotnes process, kas nodrošina āru transportu klientiem, lai loģistika būtu vienkāršāka. Nebūt ne jums kā lietotājam vai uzņēmumam, mēs darām visu, lai atbilstu jūsu prasībām un pārvadātu fibrozu lasers mašīnu tur, kur tā jādod droši, ātri un efektīvi.

Liaocheng Xianming nodrošina 30000 kvadrātmetru ražošanas vienību. Mums ir nozares virsrakstīgākais R un D nodaļa, un pašlaik mēs koncentrējamies uz dažādu veidu fibrozas lasera mašīnu radīšanu.

Liaocheng Xianming īpašu uzmanību pievērsīs pēc pārdošanas atbalstam, zinot, ka labu pakalpojumu sniegšana laser mašīnām mums ir vienlīdz būtiska. Mēs sekosim principiem, kas saskan ar globālu un klientu orientētu klātbūtni. Tas iespējams ar atbalsta tīkla pakalpojumiem.

Autortiesības © Liaocheng Xianming Laser Co., Ltd. Visas tiesības aizsargātas. - Privātuma politika-Blogs