Scopri il mondo della tecnologia di taglio a laser fibra con doppia tavola per la produzione.

Hai mai davvero riflettuto sul vasto processo di produzione delle cose che usiamo quotidianamente? Gli oggetti su cui dipendiamo sono spesso realizzati con macchine progettate per tagliare, modellare e affinare materiali a livelli sempre più minuti. La Dual Table Fiber Laser Cutting Machine rimane una di queste macchine futuristiche.

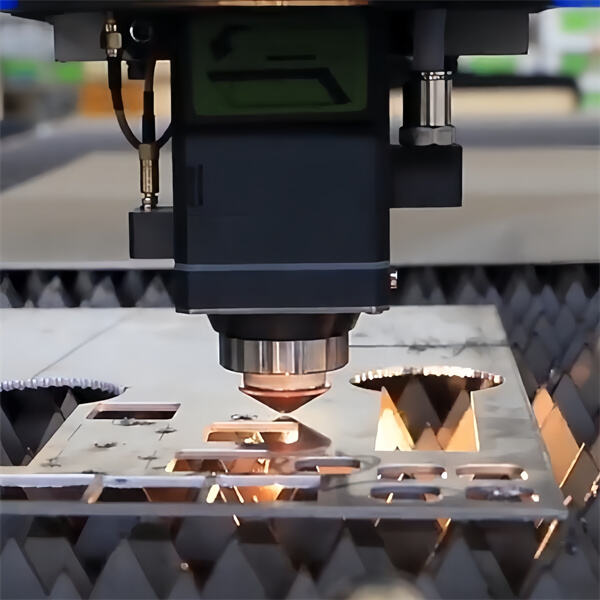

La Dual Table Fiber Laser Cutting Machine è un segno di progresso tecnologico, che garantisce un prodotto di prima classe senza difetti durante la produzione. Questa macchina offre ai costruttori precisione nei tagli secondo specifiche esatte e disegni complessi resi possibili grazie alla tecnologia avanzata del laser fibra, che garantisce un minimo spreco. La Dual Table Fiber Laser Cutting Machine dimostra anche la sua flessibilità quando viene utilizzata per tagliare una vasta gamma di materiali, da metalli a plastica e persino legno.

I processi di produzione tradizionali sono solitamente molto complicati e lunghi. Ma ora, la Macchina per Taglio Laser a Fibra con Tavolo Doppio arriva come nostra unica soluzione per aumentare automaticamente la tua produttività il doppio. Hanno sistemi a doppio tavolo che possono tagliare due materiali contemporaneamente, il che aiuta a minimizzare i tempi di taglio dovuti al cambio di materiale tra i tagli e risparmia tempo di produzione complessivo. Il risultato immediato è che le aziende potranno ridurre i loro tempi di consegna e aumentare proporzionalmente l'output del prodotto finale.

Inoltre, questo dispositivo ha caricamento e scaricamento automatici per aiutare ad aumentare la produttività della tua linea di produzione. In generale, questa macchina innovativa incrementa la produttività in varie industrie, offrendo cicli di produzione più veloci e economici.

E se stessi progettando anelli di gioielleria o complessi aggiornamenti industriali e premere semplicemente un pulsante fosse sufficiente per portare queste meraviglie alla vita? La Macchina Tagliente a Laser Fibra con Doppio Tavolo ha reso il taglio ad alta precisione una realtà. Questa macchina all'avanguardia combina una precisione nel taglio molto superiore ai metodi tradizionali, in grado di raggiungere i dettagli più intricati e le tolleranze più strette.

Questa è una differenza significativa, poiché si trova una tecnologia molto più avanzata in questa macchina tagliente a laser fibra con doppio tavolo rispetto a quelle comunemente usate nei set strumentali convenzionali. Uno dei principali vantaggi è che il suo fascio laser a fibra offre una precisione incredibile, indipendentemente dalla complessità del tuo disegno. Settori industriali che richiedono livelli elevati di precisione, come ad esempio l'area aerospaziale o le applicazioni mediche, spesso hanno tolleranze molto rigide alle quali devono attenersi affinché i loro prodotti funzionino come previsto.

E con l'arrivo della Macchina per Taglio Laser a Fibra con Doppia Tavola, una tecnologia di taglio che trasformerà la produzione e offrirà opzioni uniche per la maggior parte dei tagli retti. La sua precisione e ripetibilità rappresentano un livello senza precedenti per molte industrie che si occupano di lavorazioni con disegni complessi.

Tuttavia, una delle principali contribuzioni che questa macchina ha iniziato ad apportare in questo settore è la riduzione dei rifiuti residui e della perdita di materiale durante la produzione. Funzionando con minor potenza, la Macchina per Taglio Laser a Fibra con Doppia Tavola taglia in modo pulito e produce quantità minime di materiali di scarto, risparmiando sui costi complessivi di produzione mentre minimizza le emissioni di anidride carbonica a costi aggiuntivi bassi.

Se stai cercando di aumentare la tua produttività, il metodo tradizionale di taglio lento può essere frustrante. Ma nell'era della Tecnologia di Taglio a Laser Fibra con Doppia Tavola, nulla è impossibile. Unisce precisione ed efficienza in un unico sistema! Questo sistema automatizzato di caricamento e scaricamento della macchina riduce le ore uomo e aiuta ad accelerare il processo di produzione. E non solo, la capacità di tagliare più disegni contemporaneamente risparmia tempo e denaro.

In sintesi, la Macchina di Taglio a Laser Fibra con Doppia Tavola è una risorsa unica e di livello superiore per i produttori che valorizzano un'arte del dettaglio precisa, ottimizzando le loro operazioni attraverso l'innovazione a livelli superiori. Con la capacità di creare rapidamente e con precisione modelli 3D complessi, si piazza al primo posto a livello mondiale. Mi chiedo se una di queste macchine comparirà nel tuo laboratorio domestico nel prossimo futuro?!

Liaocheng Xianming copre un'area di 30000 metri quadrati all'interno della fabbrica e attualmente dispone di un team top nel campo, concentrato sullo sviluppo e la creazione di vari tipi di macchine laser a fibra. Abbiamo ottenuto diversi brevetti tecnici, la certificazione di gestione della qualità IS09001 e anche la certificazione CE europea e la certificazione FDA.

Liaocheng Xianming dedica molta attenzione al servizio clienti post-vendita, comprendendo che un servizio di qualità e macchine laser a fibra di qualità sono altrettanto importanti per noi. Ci atteniamo al principio di mettere il cliente al centro, con una presenza globale rafforzata da un network di supporto. Sarà disponibile un servizio online 24 ore su 24. Ci impegneremo per offrire ai nostri clienti prodotti e servizi superiori.

Liaocheng Xianming ha la capacità di fornire ai clienti il logo dell'azienda, nonché altre immagini personalizzate e progettate su misura del logo del cliente, video dei prodotti e altri media. La nostra macchina laser a fibra è di qualità superiore rispetto ad altri fornitori. I nostri principali prodotti includono un'ampia gamma di attrezzature per la lavorazione del metallo a laser ad alta potenza, nonché macchine per il saldamento a laser, pulizia e incisione a CO2.

Liaocheng Xianming Machines offre un'imballaggio professionale e una logistica progettata per fornire servizi di trasporto veloci ai clienti, semplificando la logistica. Cercheremo di rendere più semplice assicurare che la vostra macchina laser a fibra arrivi a destinazione velocemente e in sicurezza, indipendentemente dal fatto che siate un'azienda in corso o un individuo.

Copyright © Liaocheng Xianming Laser Co., Ltd. Tutti i diritti riservati. - Informativa sulla privacy- Non lo so.Blog