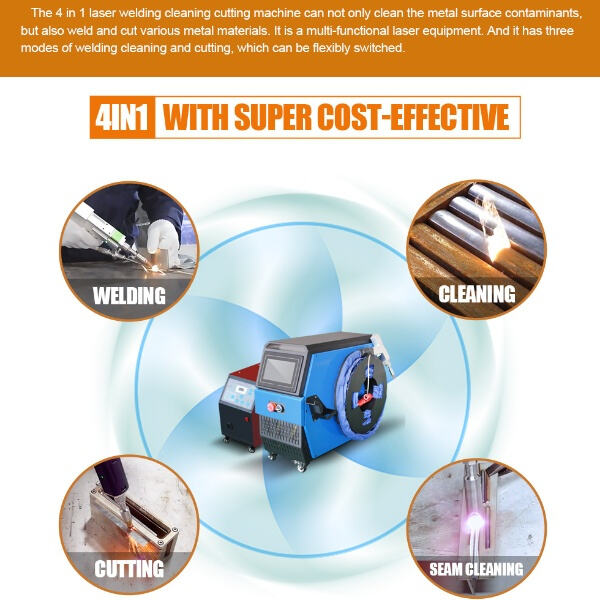

Step 1: WeldLike this awesome new thing you can weld, or cut with and even sort of engrave metal! The device is a little machine you hold in your hand that uses lasers to cut through materials cleanly and accurately. For any kind of metal worker, it is a great invention. Read more about this awesome tool here — Read the full feature list and how you can use it in YOUR projects! →

With its 3 in one air-cooled laser welding machine, if you work with metal of any kind then... The best part of it is that, you can carry it anywhere with yourself. This is very beneficial if you take multiple jobs at different places. Furthermore, this is precise—meaning you can cut and weld exactly as your need without any errors.

The laser technology in this machine is quite unlike the old welding methods. Rather than relying on fire or a high-voltage electric charge to melt metal, it does so using a laser beam. It is this why the laser can turn it into melted metal quickly and without harm to surrounding areas as well, because: A) This after all may conduct... This is a pretty solid choice for most projects, it mitigates the damage you can do to what you are working on.

Now let's say you need to take two separate pieces of metal and stick them together, this is where the welding feature would come in. When a metal has to be cut in certain shape you typically desire, this facility is used widely for obtaining the expected perfect contour. For metal work, you can personalize your piece of metal with the engraving feature if you want to add a design or logo or simply some words.

The great thing about this machine is that it functions well with light metal and heavy jobs as well. This is crucial because various welding machines are able to provide a good quality weld circuit only for different metals that have specific thickness ranges. Thin sheets are where some machines strip down, while others only do well with thick stock.

Finally, this machine comes with few additional features that will help you to work more efficiently and effectively in a workshop. For example, you are able to alter the intensity of your laser beam. You can control the temperature of that metal, and this is very useful for various projects.

The speed of the machine can also be tuned, allowing you to work at your own rhythm. Additionally, it offers you the luxury of having variable welding modes — continuous or pulse welding based on your requisites. So all of these extras allow you more control over your work allowing you to make it exactly what YOU want!

Liaocheng Xianming ha un'unità produttiva di 30000 mq. Abbiamo un reparto di ricerca e sviluppo di prim'ordine nel settore e ora ci concentriamo sulla creazione di diversi tipi di macchine laser a fibra.

Liaocheng Xianming produce clienti con loghi personalizzati, oltre a video, immagini e altri materiali. Gli agenti forniscono anche articoli personalizzati dai clienti. La nostra macchina laser a fibra tende a essere più avanzata rispetto a molti produttori, i nostri principali servizi e prodotti includono un'ampia gamma di macchine per il taglio laser dei metalli ad alta potenza, macchine per la saldatura laser, macchine per la pulizia e macchine per l'incisione a CO2, macchine per la marcatura.

Liaocheng Xianming presta molta attenzione ai servizi post-vendita, sapendo che un buon servizio di macchine laser in fibra è per noi altrettanto cruciale. Ci atteniamo ai principi che sono in linea con la presenza globale e incentrata sul cliente. Ciò è reso possibile dal supporto per la rete di assistenza.

Liaocheng Xianming Machines è un esperto di imballaggio logistico realizzato per fornire metodi di trasporto rapidi ed efficienti agli utenti che rendono la logistica notevolmente efficiente. Faremo in modo di soddisfare la tua logistica e portare la macchina laser a fibra dove deve essere rapidamente e in modo sicuro, che tu sia una persona o una piccola impresa.

Copyright © Liaocheng Xianming Laser Co., Ltd. Tutti i diritti riservati. - Politica sulla Privacy - Blog