Αν χρειάζεστε να κόψετε μέταλλο, μια μηχανή κοπής φιβερ λέιζερ είναι αδιάφορη. Αν διαχειρίζεστε μεγάλη βιομηχανική εγκατάσταση ή μια μικρή επιχείρηση, η ολοκλήρωση μιας μηχανής κοπής φιβερ λέιζερ στην παραγωγική σας διαδικασία θα ανεβάσει την παραγωγικότητα σε έναν άλλο επίπεδο. Μια από τις πιο εξαιρετικές επιλογές είναι μια ισχυρή μηχανή κοπής φιβερ λέιζερ 1500w που διαφέρει για να καλύψει αποτελεσματικές απαιτήσεις στη βιομηχανία. Αυτό το εργαλείο μπορεί να κοπεί με εύλογη ευκολία από μεγάλες απόστασεις μετάλλων με ακρίβεια, παρέχοντας ακριβείς και καθαρές κοπές μέσα σε λίγα λεπτά. Συνεχίστε να διαβάσετε για να μάθετε για τις κορυφαίες προδιαγραφές αυτού του προηγμένου εξοπλισμού και τις πλεονεκτίες.

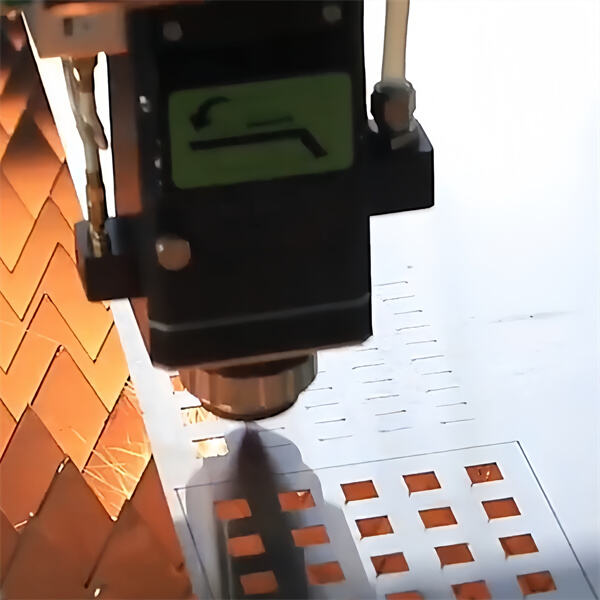

Αναμετρήσιμη Ακρίβεια στην Επεξεργασία Μετάλλων - Η καινοτόμος τεχνολογία επιτρέπει στην μηχανή κοπής λέιζερ ίνες με δύναμη 1500W να παρέχει απολύτως υψηλή ακρίβεια στην κοπή μετάλλων. Χρησιμοποιώντας ένα πολύ έντονο φαγώδες λέιζερ, το μηχανήμα διαλύει και ατμοποιεί το υλικό μετάλλου για κοπές που είναι απολύτως ακριβείς και χωρίς καμία διαφορμοποίηση. Αυτό εξαλείφει την ανάγκη για περαιτέρες εργασίες επεξεργασίας, όπως το ψαθυρισμό ή το βρυΐσιμο, εξοικονομώντας αξιόλογο χρόνο και πόρους. Επιπλέον, το μηχανήμα είναι αρκετά πολυειδές και μπορεί να χρησιμοποιηθεί για διάφορα τύπους μετάλλων όπως σίδερο, άλουμινο, κασσίτερο, χαλκός κλπ., με διαφορετική απόσταση από λίγα μιλλιμέτρα μέχρι δεκάδες εκατοστά.

Σχεδιασμένο Ειδικά για Βιομηχανική Χρήση: Η λαζέρ μηχανή κοπής 1500w είναι σχεδιασμένη και βελτιωμένη ειδικά για να χρησιμοποιείται σε περιβάλλοντα με βάση τη βιομηχανία με τοξό επί παραγωγικότητας και αποτελεσματικότητας. Το φωτεινό διαφορέμα μπορεί να κοπεί δια το παχύ κατά μήκος του μετάλλου σε λίγες δευτερόλεπτα - τέλειο για υψηλό όγκο. Αυτή η πατενταρισμένη μηχανή παρέχει υψηλό βαθμό αυτοματοποίησης με λογισμικό χειρισμού υλικών και συνοριασμού για να ροπολογηθεί ο ροής εργασίας, να μειώσει τους χρόνους ρύθμισης και να ελαχιστοποιήσει την αποβολή υλικών. Επιπλέον, η συνεχής λειτουργία της εliminates την ανάγκη για συχνή συντήρηση, αποτελώντας μινιμαλ χρόνο αδυναμίας.

Η μηχανή κοπής λέιζερ με ίξους 1500w είναι η ταχύτερη κοπής της κλάσης, με υψηλές δυνατότητες ταχείας κοπής που προσφέρονται ως πρότυπη λειτουργία. Υπάρχουν δύο ερμηνείες στο πίσω μέρος. λόγω της υψηλής εξαγωγικής δύναμής της και του πλήρως ψηφιακού συστήματος ελέγχου, μπορεί να επιτύχει μέγιστη ταχύτητα κοπής 120 μέτρων ανά λεπτό. Το γρήγορο ρυθμός επιτρέπει να ολοκληρώνονται έργα σε μικρότερο χρονικό διάστημα από ό,τι άλλες μεθόδους κοπής. Επιπλέον, η λειτουργία αυτόματης εστίασης αυτής της μηχανής διατηρεί την κοπή λέιζερ σε μια οξύτερη και ακριβή γραμμή, ελαχιστοποιώντας την αποβολή.

Επιλογή Οικονομικά Εφικτή για Μικρές Επιχειρήσεις: Το αρχικό κόστος απόκτησης μηχανήματος κοπής λέιζερ φύβερ 1500w μπορεί να φαίνεται αρκετά υψηλό, αλλά στην πραγματικότητα θα εξοικονομήσει χρήματα με την πάροδο του χρόνου. Η μηχανή λέιζερ φύβερ κοστίζει λίγα να λειτουργεί και είναι πραγματική οικονομία, αντίθετα με το plasma ή το waterjet που μπορεί να φαίνονται αρχικά φθηνότερα αλλά εξαντλούνται γρήγορα. Επιπλέον, η δυνατότητά της να επεξεργάζεται μια διαφορετική σειρά καθηκόντων κοπής καθιστά περιττά πολλά άλλα συστήματα, εξοικονομώντας χώρο και κεφαλαϊκά.

Αυτές οι μηχανές έχουν βελτιωθεί σημαντικά κατά τα χρόνια για να προσφέρουν καλύτερη απόδοση κοπής και για να εξαλείψουν την ανάγκη για αποβούρανση. Αυτά τα νέα μοντέλα που είναι διαθέσιμα δεν διαθέτουν κάποιο είδος αισθητήρα που μπορεί να ανιχνεύσει την επιφάνεια και να λειτουργεί με αισθητικό τύπο καπακιτίβιου για την ανίχνευση των επιφανειών των υλικών για αποστάσεις χωριστές από το επίκεντρο τους. Αυτό σήμαινε ότι το λέιζερ ήταν πάντα πολύ καλά τοποθετημένο, που έκανε τις κοπές πιο καθαρές και πιο ακριβείς. Εισαγάγεται η περιοχή κοπής για να δημιουργηθεί η απαιτούμενη ολοκλήρωση - ειδικά καλή για άνθρακα σταλαγμιαίου χάλυβα. Για χρήση σε μηχανές, διαθέτει επίσης μια λειτουργία βοήθειας με αέρα θείου που φυσάει ακριβή ποσότητα αερίων γύρω από την περιοχή κοπής για να αποφεύγει την οξείδωση και τις βούρες κατά την εργασία με αυτά τα υλικά.

Για να συνοψίσουμε, η απόκτηση ενός συστήματος κοπής φιβερ λέιζερ 1500w είναι μια αδιάφορη επένδυση για κάθε επιχείρηση κατασκευής μετάλλων. Διαθέτει απαράβαστη ακρίβεια, βιομηχανική αποτελεσματικότητα και δυναμικό ταχύτητας χάρη στην κοστολογικότητά της (είναι προς το παρόν η φθηνότερη μέθοδος), μπορεί να εξοικονομήσει σημαντικά χρήματα στην επιχείρησή σας και να προσφέρει υψηλή ταχύτητα κοπής, επιτρέποντας μεγαλύτερη παραγωγικότητα με εύκολα ρυθμισμένες εργασίες.

Το δίκτυο αγοράς και πώλησης μηχανών Xianming της Liaocheng καλύπτει πάνω από 60 χώρες και περιοχές. Διαθέτει επαγγελματική διαδικασία λογιστικού, η οποία παρέχει στους πελάτες γρήγορες υπηρεσίες μεταφοράς, εξασφαλίζοντας ότι το λογιστικό είναι πολύ πιο αποτελεσματικό. Προσπαθούμε να εξασφαλίσουμε ότι η μηχανή λέιζερ τους φτάνει στον προορισμό της γρήγορα και ασφαλώς, ανεξάρτητα από το αν είστε πελάτης επειδή επιχείρηση.

Η Liaocheng Xianming δίνει μεγάλη προσοχή στις μεταπωλητικές υπηρεσίες, επιγνωρίζοντας ότι καλή υπηρεσία για τις μηχανές λάσερ είναι ίσως κρίσιμη. Προσκολλούμε στα αρχήματα που συμφωνούν με την προσέγγιση πελατών και παγκόσμια παρουσία. Αυτό είναι δυνατό με την υποστήριξη του δικτύου υπηρεσιών.

Το Liaocheng Xianming έχει την ικανότητα να προσφέρει στους πελάτες ένα λογότυπο καθώς και άλλα προσαρμοσμένα και προσωπικά σημειώματα που μπορούν να επιχειρηματοποιηθούν με τον λογότυπο του πελάτη, φωτογραφίες προϊόντων, βίντεο και άλλα προϊόντα. Το μηχάνημα φιβερ λέιζερ είναι καλύτερο από άλλους κατασκευαστές.

Η Liaocheng Xianming καλύπτει ένα στοιχείο των 30.000 τετραγωνικών μετρών στη γεωργική εγκατάσταση και έχει τώρα μια κορυφαία ομάδα στο πεδίο, επικεντρωμένη στην ανάπτυξη και δημιουργία διαφόρων μηχανών φιβερ λέιζερ. Έχουμε αρκετά πατέντες που έχουν αποκτήσει την πιστοποίηση ποιότητας IS09001, καθώς και την πιστοποίηση CE της Ευρώπης και την πιστοποίηση FDA.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Πολιτική Απορρήτου- Τι;Ιστολόγιο