Прочетете:-Файбър Лазерни Резачи: Будещето на технологията за рязане

В индустриите, които се развиват постоянно, бизнесите ще приветстват възможността да използват най-новата технология, за да не останат зад баклажаните. Една от тези технологии, която води революция в сектора на реженето, са машините за режене с филов лазер. Проектираните да извършват прецизно и ефикасно режене на множество материали като метални листове, туби или профили по най-научен начин, тези машини са произведени с най-модерната технология и гарантират най-високото качество на оборудването.

Днес ще се погълтим по-дълбоко в тази конкретна технология и ще разгледаме широкия спектър от предимства, които тя предлагат, както и нейната ултра висока производителност при обработка на големи серийни поръчки, в сравнение с оптичните лазерни режачи по природа - след това ще определим коя от тях е най-подходяща за вашия бизнес, както и ще разгледаме широките области, в които могат да бъдат използвани машините за режене с филов лазер.

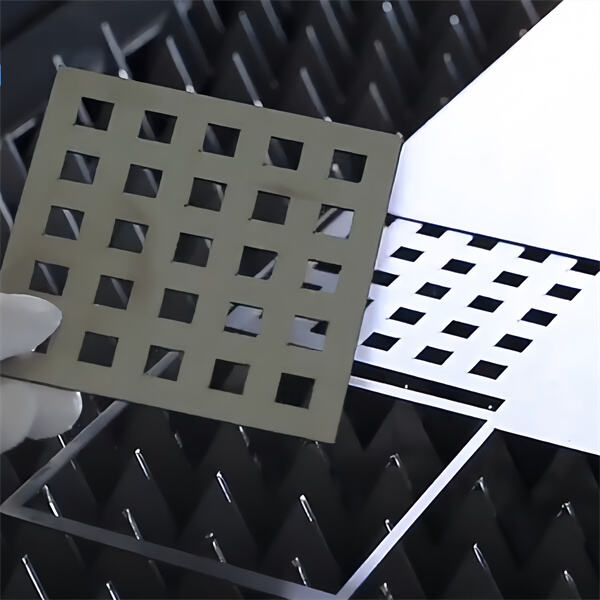

Филовите лазерни резачки машини произвеждат чисти, точни резултати, целенасочвайки материалът с високомощен лазер, който го топи или испарява. Филовата лазерна технология носи със себе си множество предимства за приложенията в металургическата индустрия. Ключови предимства включват:

Бързо рязане: Филовите лазерни резачки машини могат да рязат материали с висока скорост и са най-добрият избор за индустрии с масово производство. Нивната бърза способност за рязане ги прави идеални кандидати за множество индустрии, включително автомобилната, авиационната и строителството.

Точно рязане: Филовите лазерни резачки машини могат да рязат материали с изключителна точност, благодаря на техния вискомощен лазерен лъч. Точност: Те са много точни, измервани в микрони, така че никакъв рез не е прекалено детайлечен или сложен.

Ниски експloatационни разходи: В сравнение с другите режущи технологии, като CO2 лазери, които изискват скъпи оптични огледала и газови линзи, поддръжката на филови лазерни резачни машини е по-евтина. Това означава намалени оперативни разходи и решава голяма проблем за бизнесите, които искат да намалят производствените си разходи.

Висока енергетична ефективност: Филовите лазерни резачни машини използват по-малко електроенергия и осигуряват отлични резове. Това спестява таксите свързани с електричество и поради това е една от най-зелените опции.

При големи обеми на производство, филовите лазерни резачни машини са най-добрият избор. Скоростта на бързо рязане може да обработи по-голям материален обем за по-кратко време. Тези машини са много универсални и могат да рязат листове, труби и профили от метал лесно, което означава, че могат да се използват в различни индустрии.

За да изберете най-добрата резачка машина за вашия бизнес, трябва да вземете под внимание фактори като какъв материал се използва, който искаме да режем, или колко режи се на производствена работа и дали това трябва да се направи с екстремна прецизност. За компании, които имат нужда от бързи и точни режи, волоконните лазерни режачки машини са отличен избор. Системите за волоконно лазерно рязане са също по-преимуществени, защото компании, които имат нужда да намалат производствените си разходи, сигурно ще спестят пари, тъй като лазерната система е значително по-евтина на годишна основа. За всеки, който не е сигурен коя резачка машина ще е най-подходящата за неговия бизнес, се препоръчва да се свърже с някои професионалисти в индустрията.

Предимства при използването на волоконни лазерни режачни машини

Osвен тяхното използване като работници за производство с висок обем, филовите лазерни резачи са многофункционални инструменти, които намират приложение в различни индустрии. Тези машини са станали популярни в области като аерокосмическа и военна промишленост поради техния точност и висока скорост. Поред това, те се използват също така за рязане на материали от различни размери в автомобилната и строителната индустрия. В другия край на размера и мащаба, филовите лазерни резачи се използват във всичко от правенето на ювелирни изделия до строителни проекти, които изискват начин за рязане на стоманени листове.

Файбър лазерните резачи водят металната индустрия на рязане с ултра висока скорост, точност и широки възможности. Машината е напълно подходяща за приложения в среда с голяма производствена капацитет!!! Файбър лазерните резачи са също добри за компании, които искат да спестят на производствени разходи. Тези машини са универсални инструменти, които могат да се използват в различни индустрии. Ако още не сте определили дали файбър лазерните резачи могат да бъдат интегрирани в вашия процес на работа, тогава получаването на мнение от професионалисти в индустрията сигурно ще има положително въздействие върху това важно решение.

Ляоченг Сянминг е много внимателен към следпродажните услуги, знаейки, че отличната услуга за филови лазери за нас е с равна важност. Придържаме се на принципите, които са духът на клиентския център и глобалното присъствие. Това става възможно благодарение на поддръжката на нашите мрежи за услуги.

Ляоченг Сианминг дава на клиентите си персонализирани логотипи и изображения, видеа, както и други материали. Агентите често предлагат маркирани продукти от клиентите. Лазерната машина е много по-добра от мнозинството други доставчици.

Продажби на машини Xianming от Ляоченг плюс маркетингова мрежа, която се разтега над 60 страници и региони. Тя предоставя професионален логистически процес, който осигурява клиентите с бързи транспортни услуги, гарантирайки, че логистиката става по-удобна. Независимо дали сте потребител или просто бизнес, ще се стремим да бъдем най-добри при изпълнение на вашите нужди и да получите филоволна лазерна машина там, където трябва безопасно и бързо.

Ляоченг Сианминг заема площ от 30 000 квадратни метра вътре в фабриката, където се намира изключителна екипировка за РИ Д на пазара и се занимава създаването и развитието на различни видове филови лазерни машини. В момента имаме няколко патента в областта на технологията и сме получили сертификация ISO 9001 за контрол на качеството, както и европейската сертификация CE и FDA сертификация.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Политика за поверителност - Блог