Then, in the welding world something new emerged - a handheld laser for welding! Before these maverick machines came into being, the majority of welding work was performed with cumbersome and stationary equipment that present difficulties working on delicate or inaccessible areas. But the introduction of portable laser welding equipment has shaken up this balance, and for those in small scale applications a whole host or benefits that enhance both efficiency and precision are now achievable.

Hand-held laser welding machines have changed the way that we approach and perform welds, allowing us to create more accurate results than many other common techniques. These machines emit a thin laser beam that is focused on the desired area, leading to highly accurate welds in hard-to-reach locations with very little effort.

What Are the Benefits of Handheld Laser Welding Machines for Small-Scale Pieces.

The capabilities of hand-directed lasers offer flexibility suitable for a broad range of applications such as welding intricate pieces jewelry, fragile dental work and critical airplane components. There are many advantages of working with these machines including:

Exactness: Laser technology offers excellent exactness in welding small details due to the focused nature of its laser beam making it possible for welders to work with high precision.

Control: The ability to control the intensity and pace of laser beam gives welders flexibility to customize their welding speed as per the specific needs that lead in impeccable outputs.

Quality: Handheld laser welding devices are noted for the liberty with which they can be used to conduct high-speed, exact welds that ultimately benefit both those kind enough as well as their clients.

Handheld laser welding machines are portable and provide an on-the-go solution for welders that need to be mobile across many locations. They shine in the form of these light and forgiving machines built because:

Thanks to their portability, the use of these machines makes it possible for welders not only for on-site welding activities but even to work in remote conditions - an unprecedented flexibility at job.

Time savings: The streamlined set-up process and minimal travel requirements save time, allow the welding process to start sooner with portable handheld laser welders.

Affordability: Besides being easier to use, portable welding machines are also a cheaper option than the large industrial machinery increasing every saving in the purchase and working of equipment.

The implementation of Handheld laser welding machines in areas such as the automotive, Aerospace and medical industries have since then changed how manufacturing is done through;

Another way you can position it better is by writing that: STREAMLINING PRODUCTION TIMELINES - Handheld laser machines have the speed to take projects through our manufacturing process quickly and efficiently which allows us to meet stringent market demands with relative ease.

Guaranteed Excellence: As laser welding is both precise and uniform, it yields quality welds that live up to high industry standards-ultimately improving the overall quality of your products.

Handheld laser welding machines have proven to be versatile in the types of materials they can weld from aluminum, titanium and stainless steel which means manufacturers would only require one machine that is now able to support a wider range of production.

In precision laser welding, handheld systems provide an important function in streamlining manufacturing processes across almost all industries:The advantages of a hand-held can be summarised as follows

Fast-tracked Production: By speeding up welding times, these machines diminish production phases and allow manufacturers to meet orders in quicker intervals.

Increased Capabilities: The ability of portable laser welding machines to handle an array of projects and materials opens up new paths for manufacturers, making them more versatile in the market.

Cost Savings in Driving Mode: Being pocket-friendly and easy to launch as well as carry out, handheld laser welding devices can be a sound means for companies to cut back operational costs plus increase profits.

While much has been said in its favour, the fact remains that handheld laser welding machines are simply too versatile to ignore by forward-thinking manufacturers specializing in a new range of products for which conventional methods and systems will fall short. By incorporating these innovative tools, manufacturers are expected to gain increased work output through a greater scope of welds and an abundant level of cost savings in their welding activities.

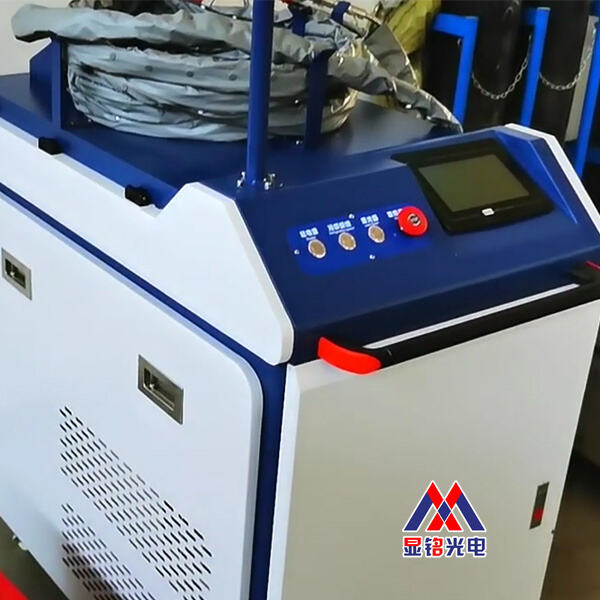

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming machines markets and sales network that spans over 60 countries and regions. It has a professional logistics procedure, which supplies customers with quick transportation services, ensuring that logistics is much more efficient. We are going to try our safer to ensure which their fiber Laser machine gets to its destination quickly and safely, no matter whether or otherwise not your are a client given that business.

Liaocheng Xianming gives customers and custom logos plus images, videos as well as other materials. Agents are also able to deliver customized things by customers. Our fibre laser machine is preferable to other manufacturers.

Liaocheng Xianming covers a spot of 30000 square meters in the factory, is sold with a D r excellent team the field, plus is concentrated regarding the creation and development of varied kinds of fiber lasers. We have many patents being technical and contains now passed on the IS09001 quality management certification aswell as European CE certification plus FDA certification.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog