Are you THINKING of BUYING a Fiber Laser Cutting Machine?

Considering investing in a fiber laser cutting machine? If the answer is yes, then you will need to keep in mind a few important things before going ahead with this action. Machines can range in price from a few thousand dollars to several hundred thousand dollars. Once you are ready to decide, be sure and research the machine sizing (laser power level and cutting bed dimensions), in addition to its speed and preciseness of cut.

Just as critical is the software and controls to make the machine run. Although better software and control may cost more, they would easily pay for themselves by making you much smarter manufacturers that lose less downtime due to miscalculations.

Purchasing a fiber laser cutting machine is no small investment, and can range from $20,000 to over half-a-million dollars (before taxes or shipping), plus the costs of operating it. You have to account for all your expenses, transportation fees, installation costs, power consumption etc.

And if you need to keep your initial investment low, we have some fiber laser cutter machines for sale under $50.000. While these machines won't offer as high quality of a job relative to more expensive options, they still get the job done though requiring additional efforts. That said, for the price point, MIG welders and TIG machines are typically a budget-friendlier option than fiber laser cutting practical applications.

In this guide, we will discuss the major benefits of using a fiber laser cutting machine and how they can be beneficial for small to medium businesses. They not only work at fast pace but also provide an ultimate level of perfection that increases the production efficiency and decreases the wastage of material. Of course, every business will have to weigh its particular needs and finances (bearing in mind ongoing expenses), such as power consumption or maintenance costs.

In addition to compressing processing tasks, fiber laser cutting machines are crucial in aiding the progression of different industries. But, as Allaire noted already-one has to keep in mind here that the price tag for these machines is fairly hefty and would depend on various factors. It will be a wise decision to make the comparison of cost and features prior purchase. With prices lowering, more and more companies have been able to take advantage of fiber laser cutting machines in their manufacturing process-lowering the labor costs associated with decreased lead times while raising throughput due to faster speeds.

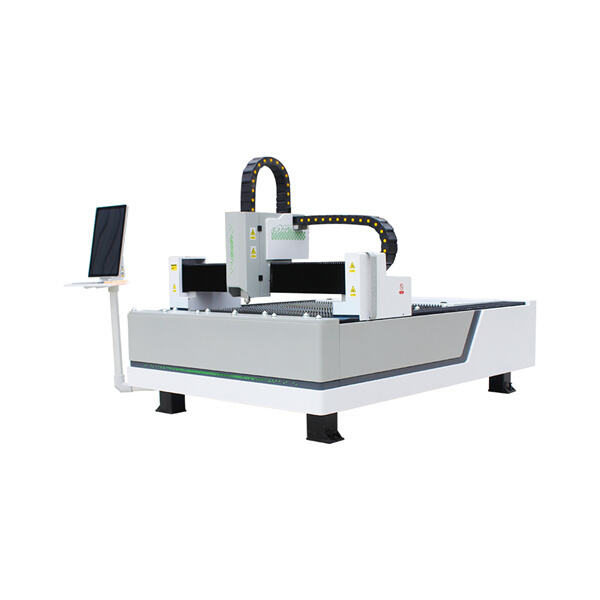

Superior quality Industrial Fiber Laser Cutting Machine If you are shopping around for a fiber laser cutting machine, it is important to scrutinize prices and specifications so that you can make an informed purchase. The price paid for these machines can range from a few thousand up to hundreds of thousands of dollars. That includes looking at the power output of the laser, how big a cutting bed it has and its cutting speed as well precision along with just how sophisticated are they software and controls.

Also, critical should be the examination of software controls with an eye towards whether or not a machine can do what its brain tells it to. Improved software and controls can help please productivity, reduce downtime, And minimize cutting inaccuracies. On the other hand, these advanced features may increase the price of this machine in general.

What Are The Types of Costs you Should Pay While Buying A Fiber Laser Cutting Machine?

Factors Affecting the Total Investment Cost of a Fiber Laser Cutting Machine For one, the robot itself costs between $20000 and more than half a million dollars. Moreover, costs for transportation or installation can also go up to tens of thousands of dollars (this would vary depending on the size and location in place).

Also, do not forget the living expenses as current fees of electricity and maintenance costs. These machines take a lot of electricity to operate and you need to find out how much this costs before making any further purchasing decisions]]) The maintenance costs can change with the complexity and design of the machine.

Related Story: Here's What We Think the 2021 Ford Bronco Will Actually Look Like(features trim summery) View Related Story: These May, or Already Are,Priced Out of All Acceptance P...

So, the variety of affordable fiber laser machines are more or less limited; there exists several cutting machine options on the market that have a specification not exceeding $50. Top models in this price range include the Bodor P3015 1KW fiber laser cutting machine, Triumph Fiber Laser Cutting Machine and Trotec Speedy 400 flexx.

These models are priced in the midrange, balancing lower power output from the laser, smaller cutting bed areas and other capabilities with their price. While they come in at a lower price, but give you confidence to know that your prints are taken care of without having to upgrade air cutting solutions for many small businesses.

Fiber laser cutting machines have dropped in price considerably over the years. This decline can be accredited to a variety of facets which are associated with the growth in laser technology, tougher market competition and better manufacturing practices.

As pricing has gotten more competitive and technologies have improved, so too have the capabilities of fiber laser cutting machines. Those machines have vastly improved in power, with greater laser outputs and greater cutting beds as good new software iterations. This has led to dramatic changes in the pricing for fiber laser cutting technology, now available at a price which is within reach of smaller businesses that used to be priced out.

While fibre laser cutting machines might be an investment too rich for a lot of small and medium enterprises, they have many advantages. They help companies get exact cuts save time an also reduce material loss thus increasing production efficiency. Then, they offer a level of cutting accuracy that is almost unachieveable from alternative streaming techniques.

Those looking to invest in a fiber laser cutting machine must do some serious contemplation when it comes to their needs and budget constraints-especially small businesses. There are many options that the market provides for all kinds of budgets and requirements. One also has to take into account the running of an electric car i.e. electricity consumption and maintenance, in order for it to be a viable option over time....

Today fiber laser cutting machines have become essential, as this equipment allows for precision cuts in a variety of industries. The amount you invest in all of this can very widely based upon many factors, but be sure to perform a lot of research on the costs and features before pulling the trigger. For smaller businesses, there are many machines available for under $50k that offer both affordability and capability. Advances in production techniques because of lowering costs mean a wider selection of firms can use new technologies and higher accuracy models such as fiber laser cutting machines.

Liaocheng Xianming machines market and sales network across significantly more than 60 countries and areas, include a professional logistics procedure which supplies customers with quick transportation services making sure that logistics gets to be more convenient. If you should be a person as an ongoing company we does our far better satisfy your desires and transport your fiber laser machine to its location swiftly and safely.

Liaocheng Xianming gives customers with customized logos and images, videos along with other materials. Agents are often in a position to provide branded merchandise by customers. The fiber Laser machine is way better to many other providers.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming covers a location of 30000 square meters factory is home to an outstanding r D team in the business enterprise. These are typically dedicated to the development and creation of numerous kinds of fiber lasers. We now have several patents that could be technical. We've been awarded the ISO9001 quality management system certification and european CE certification certification.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog