One of the most amazing uses or technologies in fiber laser cutter pipes is an extremely high-power laser used to achieve precision cuts on depending whether it will be a tube or pipe, similar project requirements. And This most complicated cutting is best suitable for very precise and superior quality require industries.

Fiber laser cutter pipes work by shining a focused beam of light at the surface of pipe, which mirrors then guide to make precise cuts. Strength of the laser: It can cut any pipe and tube even though its thickness is high

Pipes cut using fiber laser cutter offer exceptionally high precision, so you can depend on the to perform even demanding cuts with great detailing. Furthermore, this technology is faster and more efficient than other cutting methods.

It can be hard to choose the right fiber laser cutter pipe for you with so many options out there. This should be determined based on your industry and the materials that you need to cut, what size or thickness are these.

The most critical considerations for choosing a fiber laser cutter pipe are the power output of the laser, cutting speed and precision. Lasers with more power cut faster and are capable of being used on a wider variety of materials.

Also, You need to make calculation on the initial price of laser cutter pipe alongside with its maintenance and repair charges. While a more cost effective option might be enticing, over time they could end up costing the maintenance expenses to go through...

In this article, we will introduce the beam quality and how fiber laser cutting technology benefits pipe Cut-off applications. Unmatched accuracy, for every cut is perfect no matter how complex.

In addition, fiber laser cutting technology is highly versatile able to cut a variety materials and thicknesses. This makes it a very useful tool in industries such as automotive, aerospace and construction.

One of the key advantages that comes along with fiber laser technology is its unprecedented velocity - it slices through pipes and tubes far more quickly than traditional alternatives. In addition to being an eco friendly technology that is 99% waste free and uses very little power.

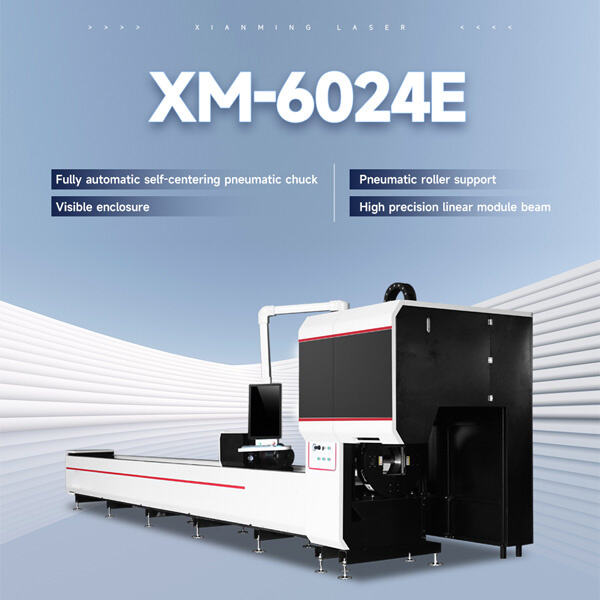

The natural evolution of recent developments in fiber laser cutter pipe technology are changing the way industry operates around world. These best of the breed machines have a high level accuracy, speed and efficiency making them suitable even for most challenging projects.

One important advancement with fiber laser cutter pipe technology is that it has become possible to cut through thicker materials. This makes it possible for industries that work with heavy pipes and tubes to get the benefit of using this technology, because Due to which if there is a change in one piece then all pieces will get his proper grip.

In addition, the machines are further laced with automation features that significantly add to its efficiency by reducing manufacturing time and subsequently improving productivity over all.

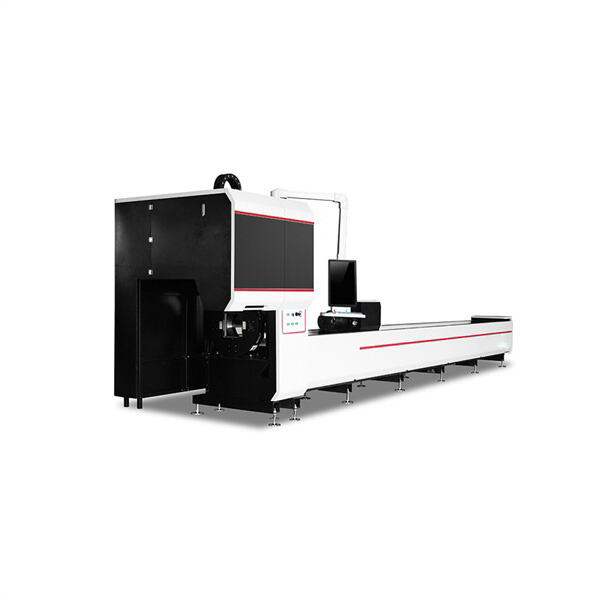

Fiber laser cutter pipes are versatile tools that come in numerous designs suitable for use in different industry fields and applications. They are even able to cut through steel, aluminum, copper as well as brass pipes and tubes in no time.

Fiber laser cutter tubing greatly benefits the automotive industry as heavy duty metal pipe is rapidly and with high precision, cut to fabricate complex vehicle parts.

Likewise, the aerospace industry makes use of fiber laser cutter pipes to aid in cutting through materials like titanium and stainless steel that allow for precision parts on airplanes.

Ultimately, Fiber Laser Cutter pipes prove to be one of the most advanced and profitable cutting tools for all contexts in any field. They work accurately, quickly and with little environmental impact across their full of branch operations; a great value for businesses hoping to improve the productivity methods in place. As fiber laser cutter pipe technology continues to advance, we will see a much broader horizon opening with revolutionary advancements in the years ahead.

Liaocheng Xianming pay much pay attention to after-sales services, and know that a good after-sales service and high quality fiber laser equipment is same important for us will adhere to the principles of keeping with the global, customer-focused presence bolstered by the support of service networks, and it will offer 24/7 on-line service. We will strive to offer the customers with more superior products and superior service.

Liaocheng Xianming covers a 30000 place square meters of factory, has an excellent r D team into the field. We are centered on the developing and design for assorted fiber lasers. We have several often patents technical have passed the IS09001 quality management certification system because well as European CE certification plus FDA certification.

Liaocheng Xianming can provide clients and logos as well since other personalized and agents with images for the customer's logo, product, videos as well as other items. Our fiber laser machine has a top quality than|top quality} other providers, our primary merchandise include a wide range of high-powered metal laser cutting machines, laser welding machine, cleaning machine, and co2 engraving machine and marking machine.

Liaocheng Xianming machines market and sales community across over 60 countries plus regions. It is a very efficient logistics packaging procedure that provides speedy transport to your visitors in order for logistics try made easier. It does not matter if you should be the user or a company We do our better to meet your requirements plus transport the fibre laser machine to where it takes to securely be quickly and.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog