Read Also: How Fiber Laser Cutters are Changing the Precision Engineering World

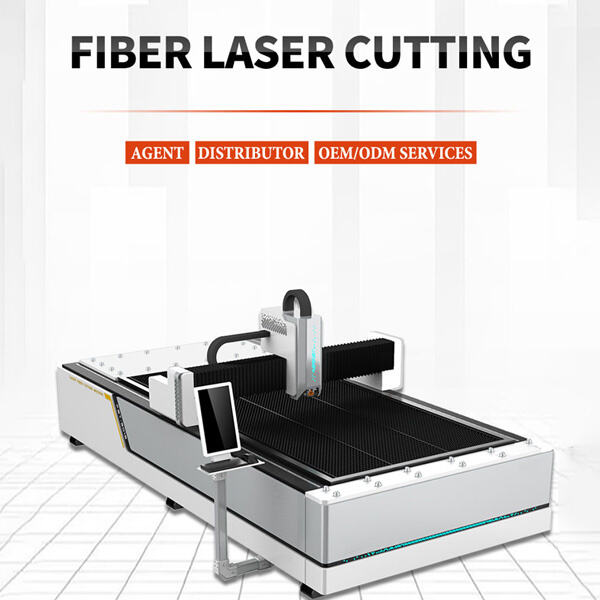

Today, fiber laser cutters have become one of the most essential tools in production and manufacturing. These amazing machines that are globally known for being extremely fast and precisely accurate, are used to cut materials in different sizes with geometrically perfect cuts. Fiber laser cutters enjoy a considerable segment of the market in many industries because they are both effective and reliable from an engineering, as well as manufacturing perspective. During the following sections, we will go deeper into the High-Precision Fibre Laser Cutters market analysis that features various contingent facets and present precise characteristics to resolve future predictions on your behalf. We examine top 5 options for precision engineering; fibre laser technology has advanced manufacturing processes within multiple industries triggering new opportunities with a particular focus on metal fabrication showcasing innovation in functionalities accompanied by benefits they have brought along their ways.

Fiber laser cutters are the ultimate type of tools for moulding well-formed and intricate, delicate parts with unmatched precision. The Mazak Optonics FabriGear 300, Amada FLCAJ series and the Trumpf TruLaser series are all worthy of special mention for their accuracy due to sheer precision engineering techniques. With advanced features like ultrahigh speed cutting, automatic nozzle changers and the latest control systems these machines are a perfect choice to ensure both superior production in terms of cut as well engravable finish.

The arrival of fibre laser cutters has significantly changed the manufacturing scenario, providing unbeatable velocity and precision for fabrication operations. These versatile modern marvels are able to do anything from engraving or cutting, welding and marking. By using up-to-date technology fiber laser cutting systems are able to give faster and more precise cuts that results in increased productivity at a lower production cost. Fiber laser cutters have created more opportunities for quick and easy manufacturing of incredibly complex patterns in a variety of shapes, with little to no material waste possible by streamlining the traditional processes.

Among metal fabrication tools, fiber laser cutters have revolutionized the cutting of a wide range of descrying metals including aluminum, brass and copper in addition to stainless steel at incredibly high Velocities. Due to this precision cutting feature their usage is also high and growing in metal fabrication tasks like pipe, sheet brass & bronze plate cutting machines. The Trumpf TruLaser series, Mazak Optonics Series and Amada FLCAJ Series are some of the big players in this game, who have not hesitated to move up with Fiber laser cutters for there faster speed & accuracy when dealing with intricate metalwork.

Achieving State-of-the-Art Speed and Accuracy with the Help of Fiber Laser Cutting

The number one perk of owning fiber laser cutters is hands down the high-speed and highly accurate cutting technology they deploy. Utilizing these advanced machines allows for impeccable speed and precision, allowing manufacturers to produce detailed designs in a fraction of the time it used too. Fiber laser cutters are also designed using laser cutting technology to prevent material wastage that is inherent in traditional methods, streamlining the process and reducing overall costs. These cutters are provided with speech recognition software, which takes the accuracy of cutting processes to an altogether different level and helps engineers detect errors thorughout the process.

Fiber laser cutters have redefined the standards of operational practices in industrial manufacturing, facilitating companies to deliver sharp parts at jaw-dropping speeds and hence escalating profits. Although most often seen in logistics, these incredibly flexible machines can be used by almost anything from the metalwork to textile industry. Fiber laser cutters have completely changed that by flattening out the design to an accuracy almost perfect, and in doing so they are now revolutionizing what we thought possible for industrial manufacturing with new levels of precision unmatched efficiency.

Ultimately, with their high-tech nature and outstanding abilities, fiber laser cutters are significant in the world of manufacturing. Precision engineering, metal fabrication and many other sectors are seeing the benefits of these new machines. For those who are considering purchasing a fiber laser cut, the right research and choosing of an appropriate system would be essential to properly profit from this force-changing technology down the road.

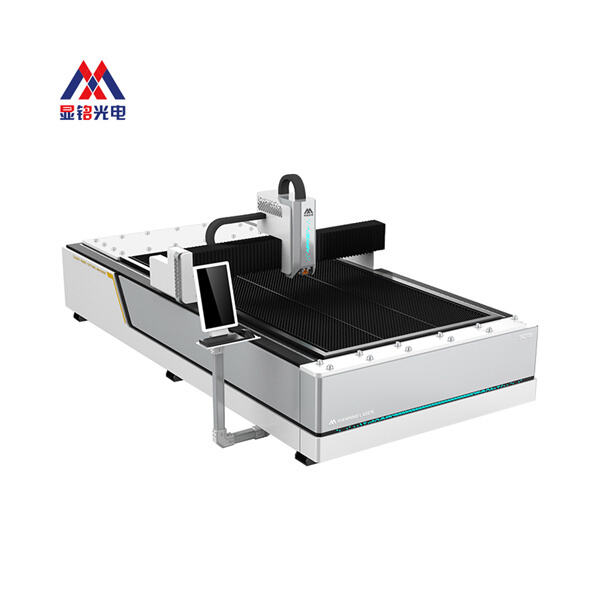

Liaocheng Xianming includes a 30000 square meters manufacturing facility. We has a r which was top d in the commercial, and we pay attention to the manufacture of numerous types of fiber laser machines.

Liaocheng Xianming gives customers with customized logos and images, videos along with other materials. Agents are often in a position to provide branded merchandise by customers. The fiber Laser machine is way better to many other providers.

Liaocheng Xianming is very attentive to after-sales and support services, knowing that having excellent service for fiber lasers for us are equally vital. We stick to the principles that are the spirit of customer-centricity and global presence. This is made possible through support for our service networks.

Liaocheng Xianming machines markets and sales network that spans over 60 countries and regions. It has a professional logistics procedure, which supplies customers with quick transportation services, ensuring that logistics is much more efficient. We are going to try our safer to ensure which their fiber Laser machine gets to its destination quickly and safely, no matter whether or otherwise not your are a client given that business.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog