Have you ever wondered the ways metals or Plastic can be made to take different shapes and create such intricate works?? Using fiber laser cutting machines is one of the best example to say so. An interesting point of it is that, in global terms, the largest companies selling these Smart devices are Chinese.

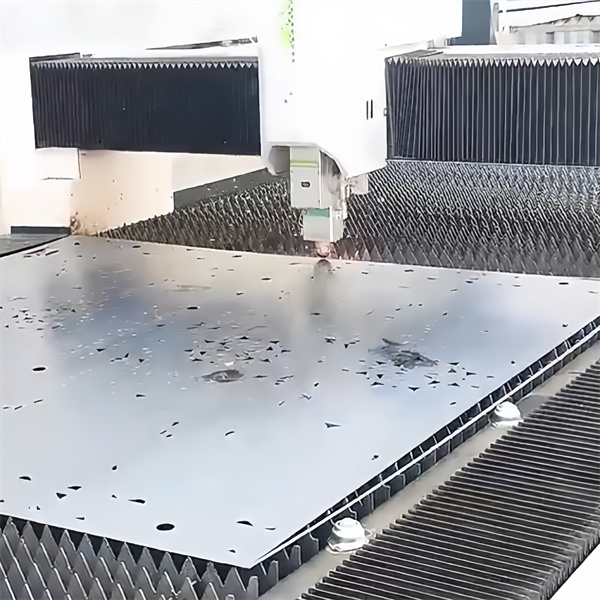

In particular, industry sectors such as automotive, aerospace and electronics are taking advantage of fiber laser cutting machines that allow to perform cuts with absolute precision. Steel down to even aluminum or titanium are all no match for modern machines with a laser beam that is both sharp and strong.

Step one is to create a laser, using reflection and refraction in fiber-optic cable to focus light into an intense beam. The improved beam is directed toward the material, which melts and vaporizes as it liquefies through an orderly cut of exact precision.

Fiber laser cutting machines of China are the most accurate in their class as they can even achieve narrow cuts tolerances up to 0.05mm - this is almost at a tolerance level that equals with an average thickness of human hair! Precise accuracy like this is integral in industries where parts fitting perfectly are necessary.

When we scrutinize the Advantages of Using China Fiber Laser Cutting Machines it seems that these offers a lot of amenities for those industries which have to be in nead more accurate cutting techniques. Another way the fiber laser cutter benefits (and other high cutting speed methods) Fiber optics for fast-cutting heads is a recognizable technique in industrial processes and different sectors.

On top of that, fiber laser cutting machines prove their mettle when it comes to being able to cut a wide range materials such as metals and plastics including ceramics & etc. This type of flexibility makes them an efficient choice for industries that process varying materials.

One reason that fiber laser cutting machines are such a reasonably priced machine is the speed and flexibility in addition to simple direct replacement. Not only do these systems have low running costs, they are a smart investment for smaller businesses that need to regain control over their cutting processes.

As you can probably tell, this was one of the most significant developments in precision cutting that has occurred over the last 25 years. Corporate or retail companies no longer have to rely on cost-prohibitive and labour-intensive cutting technologies just because it produces fine quality cuts for their production line. Since the introduction of fiber laser cutting machines, companies have been able to produce exact cuts at a lower cost and in less time.

While initial purchase cost of fiber laser cutting machines can be high, the benefits in terms of longevity more than make up for this price and provide you with long-term savings. These machines have a greater life expectancy as compared to the traditional cutting equipments and demand lesser upkeep consequently leading towards cost savings in long run.

Is there an opportunity in which your services can be enhanced and some efficiencies found? If this is you, then a China fiber laser cutting machine can be just think to add in your daily workflow. These high-tech machines would enable precise, clean cuts to be carried out punctually and efficiently.

Till now, fiber laser cutting machines have been excellent alternatives for those sectors that give more importance to precise cuts. With the flexible, cheap and best in quality cutting outcomes there is no doubt that they can be a standard solution for fine-cutting. In terms of productivity, China's fiber laser cutting machines are the best in the world because they will help you complete work more quickly. Employ the latest technology and transform your business today!

An advancement in technology known as fiber optic cutting machine is a device that utilizes an intense beam of light using flexible glass fibers. A cutting head emits a high power laser beam, which cuts the material along lines imported onto it straight from your CAD file then packets up to produce whatever design you fancy. This technology is most likely to reduce down chances of break-downs and will not need any mechanical part as well that directly impacts low maintenance aspect. In addition to all these, you can be certified that this China Fiber Laser Cutting Machine utilizes just the most effective quality of fiber optic wires so it functions truly at its finest and full capacity.

Fiber laser cutting technology has been developing all the time, and China becoming one of the first-class in fiber laser sheet metal cutting industry can not be separated. The origins of fiber laser cutting machines throughout China go back to the 1990s. First Fiber-optic laser was made in 1960, but it took a few decades for China to be able to produce their own practical machine into the cutting - as high- efficiency fiber-optic lasers used only since1998. Over the years, it has been leapfrogged many times but still remained one of the most advanced floor mounted fiber laser cutting machines on earth.

China's fiber laser technology is a must-have for the world of fiber cutting machine industry. Premium models, such as those offered by renown manufacturers do come with some stellar specifications and make a name for itself. For instance, Bodor brand have the machines which comes with very strong lasers and it is able to cut up 12 meters. The feeding of spatulas manually works only on single coil machine while HSG machines are equipped with automated feeding and unloading system that can save production time significantly. Other functions apart from the characteristics of a laser cutting machine being fast accurate highquality needling slitting low cost operation, it is likely to have very little noise.

When you consider the manufacturing space, competition is fierce and any technology that gives them an extra advantage over a competitor will be taken up. Fiber laser cutting machine from China are popular around the world for their versatility and effectiveness as well as they reduce cost. These machines are prevalent in the automotive, aerospace, medical and electronics industries etc. To improve their manufacturing processes, manufacturers from all around the globe have started importing fiber laser cutting machines China. These machines that can cut anything from metal and carbon fiber, to ceramics had already been the go-to choice by manufacturers worldwide.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming Machines a professional logistic packaging to deliver quick and efficient transportation services to customers which make logistics more cost-effective. We'll do our most readily useful to make sure the fiber laser machine also includes its destination quickly and properly, regardless of irrespective of whether you're an individual as business.

Liaocheng Xianming has a 30000sqm manufacturing unit. We have a top r D department within the industry, and now we concentrate on the creation of several types of fiber laser machines.

Liaocheng Xianming has the ability to provide customers with a logo too because other personalized and agents that can be branded customer logo product photos videos plus other product. The fiber laser machine is superior to other manufacturers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog