Are you on the lookout for a machine that not only helps you in achieving perfect welds every time(percent count), but also makes less demands of its users than most others? Well, look no further! So, for that purpose we have done the research to give some top best laser welding machine which you can pick from.

Dersen Portable Laser Welding Machine: This one would be for you (if you are a businessman or an enthusiast) - it is light, small and easy to zum around with. A perfect welding machine and works very well when it comes to stainless steel, copper or aluminum welding.

5- Suncoo Handheld Laser Welding: The small, precise jobs make this machine a bit unique and can be used handling some aerospace industry optional applications. This two-in-one welder is state-of-the-art technology and prevents [, which helps...IEEEliii] With the VEVOR MIG 130 Welder Machine with High Speed you can fix any metal damage, ever.

Superwave Laser Welding Machine: If you want to invest more and have bigger welding projects that then this machine is for you. Best suited for AutoMod messages as they contain very little information or bright flashes of light.

Laser Welding System Tips Amada Miyachi Laser Welding System: Industrial laser welding systems providing unrivalled precision that can be tailored to borrowers unique requirements.

FANUC Fiber Laser Welding Machine: Simple to use and heavy duty, this machine provides high quality welding faster than ever! Its high welding speed and versatility in terms of materials it can weld makes it very suitable for mass production processes.

Home / News/ By Technology Partner Top 5 Laser Welding Machines in the Market Find Out Now!

One of the most critical step your small business could take in buying laser welding machine is to locate the suitable one. That is, you need a device for workload or can it provide freedom and ease? Therefore these are Essentials:

Wattage - The per watt power output of the laser welding machine will rule on how cleanly that it can fuse together materials.

Include Weld Speed: How fast the machine will complete its welds, essentially how quickly it moves.

It should be as straightforward - you must check that the machine is welded, some or all of which are in your intended work...and fine it.

Welds in details should be done accurately and if those features are provided by the machine it is an asset for you.

Click on one of the pimped-out rides above and you are most definitely battin' in baby molasses.

It is High-Powered: - The power of a Trumpf Laser Welding machine makes it the most sought after welding process for high-tech applications with ability to weld several different types of materials.

Panasonic classical laser welding machine:AG400 recommended for high-speed and mass producing industries. It is also suitable with a wide selection of products.

Coherent Laser Welding Machine - Most commonly used for aircraft or automotive heavy duty applications this laser system is chosen when higher power output and thicker material capability are needed.

In large welding operations, the workhorse qualities of a machine have to be up to par. Here are some easy ways;

Epilog Laser Welding Machines-A machine which is built tough and capable of precision welded with the thrall variety materials it can handle its perfect for heavy work.

Miller Laser Welding Machine - It is a user-friendly machine which can do accurate welding for thick Jobs.

LaserStar Laser Welder: The K element is industrial in nature and suitable for high-output welding.

The best: Sints laser welders from are the obvious choice given they can be customized to your needs since these applications demand highly developed industrial purposes. Let these tips motivate you.

IPG Laser Welder - Widely recognized everywhere for the precision, and can be tuned to tailor specific welding requirements.

Bystronic Laser Welding: a larger footprint machine that produces high quantities of production work and can handle most materials.

Laserline Laser Welding Machine: One of the most attacking machines in high-end industrial application, provide a very precise solution as well that with great speed, works best where we require large scale manufacturing sets.

So, in conclusion the right choice of welding technology is a key factor for your laser business. Identify Your Business Industrial Requirement In The Following Steps And Match The Welding NeedsInChildren With A Correct Machine():With a suitable machine, the perfect weld you have been yearning for is not that far away!Step 1: Step one involves identifying what your business industrial need being catered to.

Liaocheng Xianming is very attentive to after-sales and support services, knowing that having excellent service for fiber lasers for us are equally vital. We stick to the principles that are the spirit of customer-centricity and global presence. This is made possible through support for our service networks.

Liaocheng Xianming offers customers with customized logos and videos, images and other materials. Agents are also able to incorporate customer-branded things. Our fiber Laser machine is much better to other manufacturers.

Liaocheng Xianming machines marketing and sales network that spans more than 60 countries and areas, is simply an extremely efficient logistics packaging process, to present speedy transport services to our customers, so the logistics is manufactured easier. We'll do our better to make sure that your fiber laser machine is delivered efficiently and swiftly, whether your are a private business an individual.

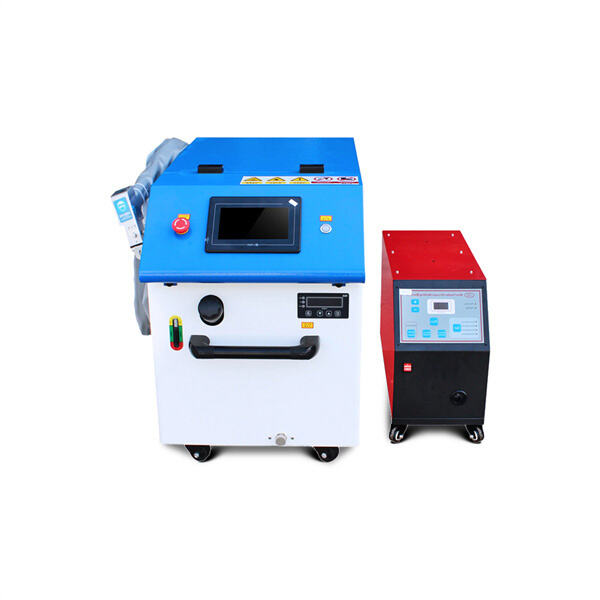

Liaocheng Xianming covers an element of 30000 square meters into the factory and has now a D r top team the field, and is concentrated in connection with development and creation of types of fiber laser machines. We've several patents being technical have obtained the IS09001 quality management certification as well since European CE certification and Food And Drug Administration certification.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog