A laser welding machine is a type of equipment that has been specifically designed to use an intense light beam in order to bond metals together. It has a very intense light for accurate high quality welds. But when it's welded, a lot of heat has to be added. Excessive amount of heat can harm the machine and yield poor results if not well managed. Therefore, the air cooling is one of the essential elements for a laser welding machine.

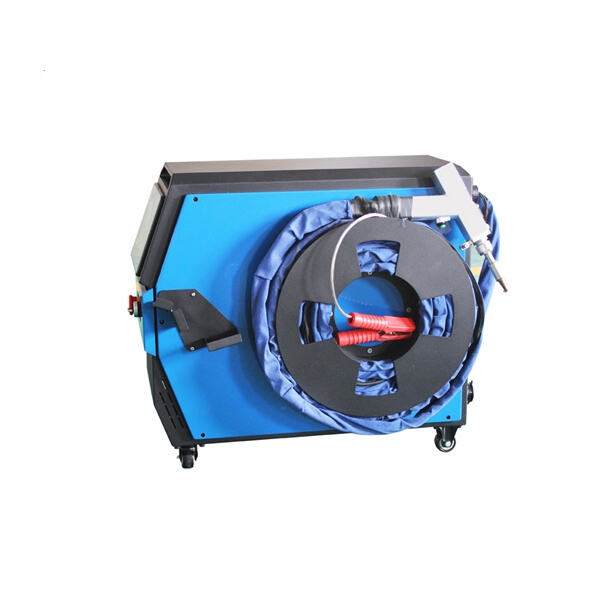

Air cooling is a fan, there to keep the welder from overheating. This helps draw heat away from the unit and in return, your system running better. When the machine is keeping a chill, it helps to make sure that welding procedure stays in maximum pleasures way and we are achieving high quality work. Proper cooling also affects the lifespan of machine apart from quality. This is highly essential as a more reliable machine can save you money in the long run instead of having to keep replacing machines.

It is simply the most efficient air cooler but somehow it never really got enough attention. It is a wise cost-effective way to increase the efficacy of your laser welding process through air cooling. It does this by keeping the machine in good working order for a longer period of time, and allows you to make professional welds without having to break your wallet doing so.

The air-cooled welding machines are designed to offer high-quality of performance in all processes. Hence, these machines are equipped with accuracy and the quality of repairing that might be invalid to a point against industry standards. Air-cooled machines are easier on power than most. That makes them more energy-efficient and also better for the environment.

Cost effectiveOne of the advantages with an air-cooled welding machine is that it tends to be a cheaper option. Air-Cooled: Unlike their water-cooled counterparts, air-cooled machines do not require you to refill a tank of water which is endlessly recycled through the system. That means you can be more efficient with your time and money, not needing to top off water levels. And, maintaining air-cooled machines is also straightforward as they have fewer items that need to be cleaned or replaced. This also makes them easier to take care of as you go along.

Not only are these air-cooled machines durable, they require very little maintenance. This is a major advantage as it translates to lower downtime in production. That allows businesses to be productive when machines aren´t running. A combination of higher productivity and lower cost often equals bigger profits for companies.

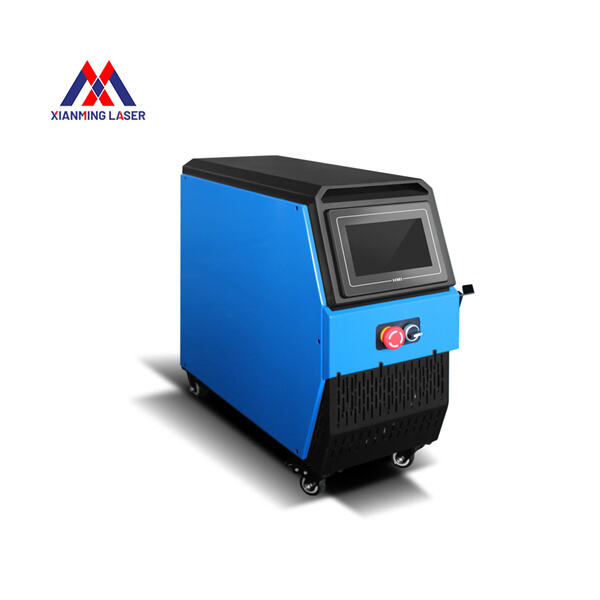

Overall, the air-cooled laser welding machine is still a very important equipment in the production process. They are efficient in delivering high-quality welds that have proved to be reliable, cheap as well. The machines promise upgraded performance with a robust build and the ability to deliver quick welding.

Liaocheng Xianming has a 30000sqm manufacturing unit. We have a top r D department within the industry, and now we concentrate on the creation of several types of fiber laser machines.

Liaocheng Xianming is very attentive to after-sales and support services, knowing that having excellent service for fiber lasers for us are equally vital. We stick to the principles that are the spirit of customer-centricity and global presence. This is made possible through support for our service networks.

Liaocheng Xianming machines market and sales network in over 60 countries and areas, has a logistics being professional procedure which provides clients with speedy transportation services so that logistics is manufactured easier. We are going to do our safer to make fully sure your fiber laser machine is delivered efficiently and swiftly, whether you're private business a person.

Liaocheng Xianming offers customers with customized logos and videos, images and other materials. Agents are also able to incorporate customer-branded things. Our fiber Laser machine is much better to other manufacturers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog