'n Faser laser snitter vir metaal is beslis 'n verbazingwekkende een, aangesien dit die proses van snit in dun bladmeterale op verskeie maniere verbeter en perfekter maak. 'n Laser masjien wat metaalwerkskapping na 'n nuwe era van presisie en spoed beweeg. Hierdie metaalfasersnitter is 'n tegnologiese verlossing geword en het die hele vervaardigingsproses getransformeer, veral in gebiede waar gebruikte metaalwerkskapping bestaan, soos skipbou, motorvervaardiging, lugvaart en bou. En dit het nie net een fasersnitter vir metaal gerevolutionseer nie, dit het byna elke deel van die vervaardigingsproses herbou. Die waterstraal is lank geleden vir die sny van super hoë-druk metaalwerker kurs steel gebruik, sowel as vir die sny van hoofmetaal soos roestvrystael, aluminium, koper en messing. Nadat faserlasersnitters geïntegreer is, is daar geen behoefte aan daardie handmatige stelsel nie en dit spaar koste en tyd van die metalvervaardigingsproses. Daar is geen beperking vir die bedryfer van 'n faserlasersnitter nie, terwyl die faserlaser-tegnologie ongekende vlakke van presisie en spoed bring tydens die proses van metaalsnit. Dit versterk die moontlikheid om areas en vorms sonder foute te prosesseer met die hulp van die gefokus straal. Die lasersnelheid wat in faserlasersnitters gebruik word, is vinniger as ander en dit sny dik metaal vinniger en doeltreffender. Faserlasersnitters revolutioneer hoe die metalwerkbond se operasies plaasvind op verskeie maniere. Een gebied waarin DMLS-stelsels die vervaardigingsproses betekenisvol verbeter het, is die vinniger en presiesere produksie van metalkomponente. Faserlasersnitters het ook die behoefte aan pleisterwelding verminder; produkteurs het tientalle ure arbeidtyd en koste gespaar. Duurzaamheidsmetavervaardiging ontwikkel deur faserlaser-tegnologie. Vervaardigers spaar tyd terwyl hulle hoë-kwaliteit metalkomponente produseer weens die vinnige sny van 'n verskeidenheid metaal soos voorspel. Daar is ook verbeterde arbeidskoste bespare in die metalvervaardigingsproses. Snybewerings van faserlasersnitters genereer minder afval, en dus meer duurzaamheid van die bewerings. So, as jy 'n stuk metaal wil kry van 'n faserlasersnitter, is dit 'n ideale een. Dit is 'n super amptelike een wat 'n kragtige verandering in hierdie bedryf veroorsaak het. Die sny van metaal is selfs vinniger en akkurater geword, beslis, aangesien dit deur sy vermoë van spoed en presisie bewys is. Dit het homself as so krities bewys in gebiede soos skipbou, motorvervaardiging, lugvaart en bou.

En die vooruitgang is nie beperk tot net een enkele fiber laser snitter metaal nie, in plaas daarvan het dit byna elke element van vervaardiging hervorm. Voorheen het vervaardigers water gebruik om met uiterst hoë druk metaal te sny, sowel as om 'n wye verskeidenheid metaal soos roestvry staal, aluminium, koper en messing te sny. Hulle is die integrasie van fiber laser snyers, wat handmatige stelselbehoeftes volkome uitgevee het en tyd en koste van die metalvervaardigingsproses bespaar het.

Daar is slegs soveel wat 'n bedienaar kan doen, maar fiber laser tegnologie bring ongekende vlakke van presisie en spoed na metaal-snybewerings. Met 'n fiber laser is dit baie meer eenvoudig om komplekse vorms sonder enige foute te prosesseer weens die gefokus straal. Boonop is die spoed van die laser wat in fiber laser snyers gebruik word veel vinniger om dik metaal effektief en vinnig te sny.

Op vele maniere dwing fiber laser snyers 'n groot verandering in hoe die metaalwerkbare branche operasie. Vinniger en akkurate produksie van metal komponente is een van die primêre gebiede waarin DMLS-stelsels aansienlik verbeter het. Die skepping van minder arbeidintensiewe prosesse het ook help om tyd en geld in metaalfabrikasie te bespaar. Laastens help die verminderde materiaalverskoning wat verbonde is aan fiber laser snyers, metaalfabrikasie na 'n meer volhoubare proses te beweeg.

Fiber laser tegnologie het die doeltreffendheid en volhoubaarheid van metaalfabrikasie aansienlik verbeter, en dit het revolusioneer hoe dit gedoen word. Vervaardigers versnel die proses van die skep van metal komponente deur vinnig deur 'n reeks metals te sny soos voorspel. Die geringere behoefte aan handmatige werk korreleer ook met 'n beter arbeidskoste. Fiber laser snyers produseer minder afval as konvensionele metaalfabrikasiebewerkings, wat toevoer tot 'n meer volhoubare praktyk.

Om kort te sê, as jy wil hê om 'n deel van die fiber laser snitmasjienvir metaal soos wat 'n verbazingwekkende een is, wat hierdie bedryf so kragtig verander het. Dit het metaal-snyprosesse selfs vinniger, akkuraater en presieser gemaak weens sy wonderlike presisie- en spoedvermoëns. Fiber laser snyers het bewys dat hulle essentieel is in bedrywe soos skipbou, motorvervaardiging, lugvaart en bou deur operasies te optimaliseer en afval te verminder.

Liaocheng Xianming het 'n 30000vm vervaardigingseenheid. Ons wil die topnavorsingsafdeling in die bedryf hê, dus kyk ons na die skepping van verskeie soorte vezellasers.

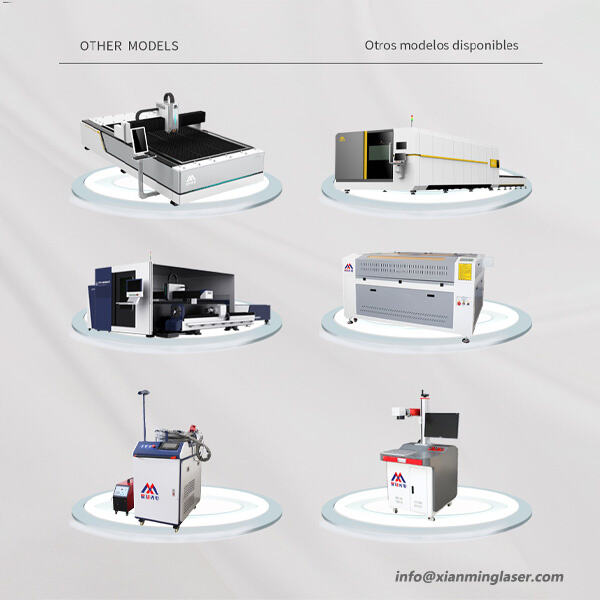

Liaocheng Xianming produseer vir kliënte met persoonlike logo's plus videos, beelde en ander materiaal. Agents verskaf ook op bestelling gemaakte items vir kliënte. Ons vezelfaser laser masjiene is meer gevorderd as dié van baie ander vervaardigers. Ons hoofdiensete en produkte sluit 'n wye verskeidenheid hoë-krags metaal laser sny masjiene in, laserweldmasjiene, skoonmaakmasjiene en ko2 graveer masjiene, merkmasjiene.

Liaocheng Xianming Masjiene bied 'n professionele logistieke verpakking om vinnige en doeltreffende vervoersdienste aan klante te lewer, wat die koste van logistiek meer doeltreffend maak. Ons sal ons beste doen om seker te stel dat die faserlaser masjien ook vinnig en korrek by sy bestemming aankom, ongeag of jy 'n individu of 'n besigheid is.

Liaocheng Xianming gee baie aandag aan naverkoopdiens, want hulle weet dat goeie diens vir laserfasermasjiene vir ons gelyksoortig kruisend is. Ons bly by die beginsels wat in ooreenstemming is met klantegesentreerdheid en wêreldwye teenwoordigheid. Dit word moontlik gemaak deur ondersteuning vir die diensnetwerk.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privaatheidsbeleid - Blog