Model: XM-12025HF

Working area:12000x2500mm

Application: Cut sheet metal

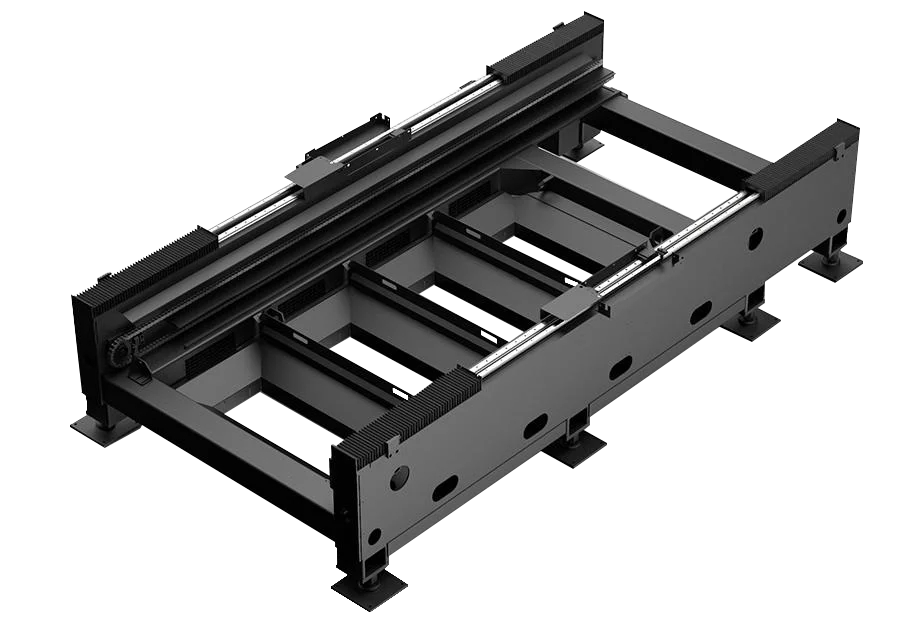

Welded base with mortise and Tenon joints

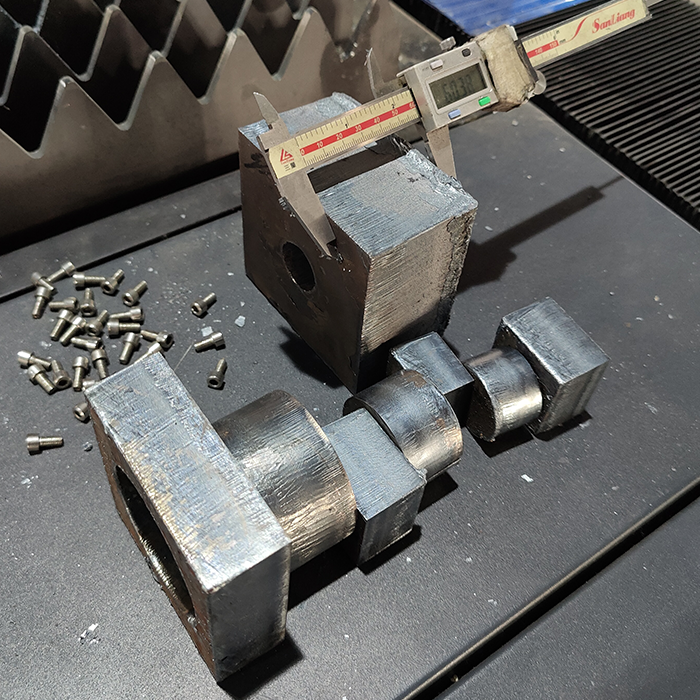

Meet the needs of full-thickness plate cutting

Color: Can customized

Cost-Effective High Value

Minimum Order Quantity: |

1 |

Packaging Details: |

1. Whole film packaging Sheet fiber laser machine; 2. Anti-collision package edge; 3. Fumigation-free plywood wooden box and pallets with iron binding belt. |

Delivery Time: |

7-40 Days |

Payment Terms: |

TT (Telegraphic Transfer), Western Union, Paypa, Alibaba Trade Assurancel. |

Supply Ability: |

300 Set/Sets per Month |

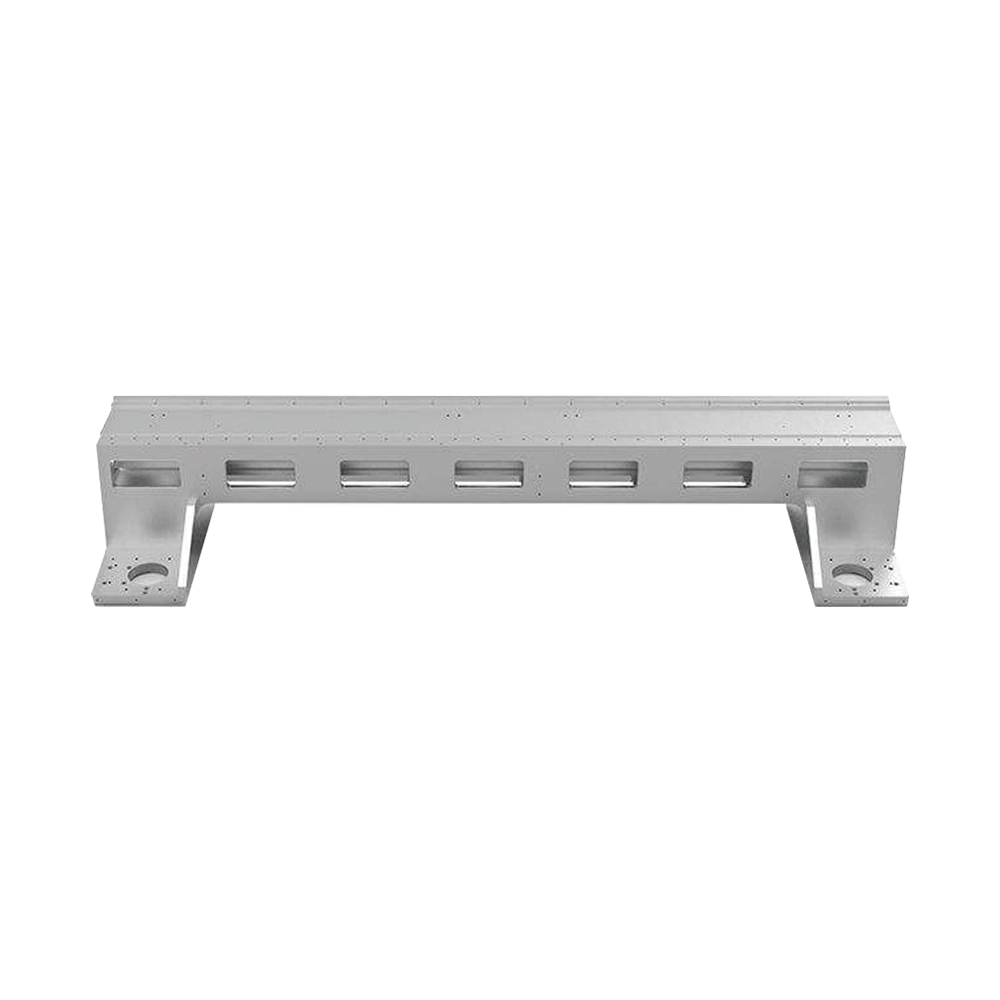

The gantry is made of high-quality aviation aluminum, which has the advantages of hard texture, high rigidity, and better stability. Improved cutting accuracy.

Lightweight design to improve the acceleration of machine tools; Significantly improved stability, surface quality, and efficiency in cutting steel plates. for this pic beside.

High and low exchange table, saving loading and unloading. Allowing the entire equipment to achieve stable cutting under high-power and high-speed operation, endowing the equipmentwith a higher standard product positioning.

Fiber laser cutting machine is suitable for metals such as carbon steel, stainless steel, brass, galvanized steel, aluminum, copper, gold, silver, alloys, iron, titanium, manganese, chromium, nickel, cobalt, etc

Fiber laser cutting machines, known for their high efficiency, precision, and low energy consumption, are widely used across various industries. Here are some of the main application fields:

Metal Processing Industry: Fiber laser cutting machines are highly popular in the metal processing industry, suitable for cutting a variety of metals such as stainless steel, carbon steel, aluminum alloys, copper, and titanium alloys. They can be used to manufacture mechanical parts, process metal sheets, create metal crafts, and produce metal signs.

Automotive Manufacturing: In the automotive sector, fiber laser cutting machines are utilized to cut auto parts like body sheet metal and engine components, ensuring the accuracy and quality of the parts.

Aerospace: This technology plays a crucial role in the aerospace field by cutting high-strength, high-temperature-resistant special alloy materials, including aircraft structural parts and engine components, which are essential for enhancing the performance and reliability of aircraft.

Electronics and Microelectronics Industry: Fiber laser cutting machines are used in the production of precise components for electronic devices, such as circuit boards, electronic chips, and mobile phone parts.

Precision Machinery: In precision machinery manufacturing, fiber laser cutting technology is employed to produce high-precision mechanical parts and components.

Advertising Production: Used for making various metal and non-metal advertisements, signs, etc. , it can precisely cut complex patterns and texts.

Construction Industry: In the construction sector, fiber laser cutting machines are used to cut decorative plates, metal components, etc. , providing beautiful and precise metal decorations for buildings.

Furniture Manufacturing: Used for cutting metal furniture parts, such as metal legs, frames, etc. , improving the product's precision and aesthetics.

Craftsmanship: Suitable for the production of metal crafts, it can finely cut complex patterns and designs, creating high-quality crafts.

Energy Industry: In the production process of new energy sources (like solar panels), fiber laser cutting technology is used to cut and process components, aiming to improve energy conversion efficiency.

The application of fiber laser cutting machines is extremely broad. With the continuous development of technology and the reduction of costs, their application fields are expected to expand further.

Model |

XM-12025HF (14025) |

Working Size |

2500*12000/2500*14000(mm) |

Laser Power |

3000W/6000W/8000W/12000W/20000W/30000W/60000W etc. |

Laser Wavelength |

1080nm |

Laser Beam quality |

<0. 373mrad |

Working Life of Fiber Source |

More than 10, 0000 hours |

Position Type |

Red Dot Pointer |

Cutting Thickness |

0. 5-10mm Within The range |

Max. Idle Running Speed |

80-110M/min |

Max acceleration |

1G |

Reorientation Accuracy |

Within ±0. 01mm |

Lubrication System |

Electrical Motored |

Cooling mode |

Water cooling and protection system |

Machine power |

9. 3KW / 13KW /18. 2KW /22. 9KW |

Auxiliary Gas for Cutting |

Oxygen, Nitrogen, Compressed Air |

Compatible Software |

AutoCAD, CorelDraw, etc. |

Handle Control |

Wireless Control Handle |

Graphic Format |

DXF/PLT/AI/LXD/GBX/NC code |

Power Supply Voltage |

220V 1Ph or 380V 3Ph, 50/60Hz |

Ultra-large fiber laser cutting machines stand out for their ability to process large workpieces with precision and speed. Its large cutting area and high power fiber lasers enable efficient processing of super-sized materials, making it an ideal component for industries that require large-scale cutting. With its advanced control system and rugged construction, it ensures reliable performance and superior productivity.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy policy

- Blog