Model: XM-3015PH (4015/6015/4020/6020/6025)

Delovna plosča: 3000x1500mm z menjavo platforme

Izjemna stabilnost

Visoka učinkovitost

Odlična natančnost

Zmanjšaj obdelno čas

Povečaj obdelno učinkovitost

Je kakšen problem? Prosimo, kontaktirajte nas, da vam lahko pomagamo!

Poizvedba|

Minimalna količina naročila: |

1 |

|

Podrobnosti o embalazi: |

1. Celotno filmsko embalovanje listovinskega vlakenastega laserja; 2. Paket proti trčenju na robu; 3. Fumigacijski brez pletve iz lesa in palet z železnim vezjem. |

|

Čas dostave: |

7-40 dni |

|

Plačilni pogoji: |

TT (Telegrafna prevod), Western Union, Paypa, Alibaba Trgovinski jamstvo. |

|

Možnost ponujanja: |

300 enot/mesecev na mesec |

|

Minimalna količina naročila: |

1 |

To je popolnoma zaklenjena metalna plošča zareznih strojev s serijo laserjev z možnostjo zamenjave platforme. Opremljeno s virom laserja moči od 1,5 kW do 30 kW, je sposobno rezati metalne plošče debeline do 25 mm. Delovno območje je od 3000mm*1500mm do 6000mmx2500mm. Popolnoma zaščiten izklopljeni način delovanja zagotavlja varnost obdelave. Imajo prednosti hitrega hitrosti rezanja, dobre učinke rezanja, nizekih operacijskih stroškov in stabilne obdelave. Ta CNC laserjni rezni stroj je opremljen s sistemom mednarodno priznanega vodilnega prenosnega sistema, nova generacija sudarskega lожeta in aluminijevih reber, novega dizajna modul za upravljanje z zrakom, optimiziranega upravnega sistema in drugih lastnosti. Laserjni rezni stroj je opremljen z novim naprednim laserjem in laserjnim reznim glavo, s prednostmi izjemne skupne izvedbe.

01. Posodobljena mehanska struktura: :Ultra hlapa aluminijeva poprečna nosilka, proizvedena z tehnologijo pritiska na 10000 ton, za ustvarjanje aluminijevih poprečnih nosilk; Oganjna, visoko temperaturno odporna in zelo dobra operacijska stabilnost.

02. Visoko-precizni sistem prenosov: Aparat uporablja servo dvojni pogon s gredjo, z obrobnim vodilom in prenosnim sistemom, komponente strojnega sistema so znamenkasti izvoz, da bi se zagotovila dolgoročna visoka hitrost in preciznost rezanja naprave.

03. Varnost in brez onesnaževanja: Popolnoma zaklenjena struktura z posebnim laserjskim varnostnim ogledalom, dim, ki ga nastopa rezanje, se lahko hitro odstrani, okolju prijazno in brez onesnaževanja.

04. Nadzorovan sistem: Med obdelavo je vsak območje kdaj koli možno nadzorovati in nadzirati postopek.

05. Rezalna glava s samodejnim fokusiranjem :Samodejna prilagajanje fokusa, primerno za rastni fokus; Brez osebne učinkovite režnje. Visoka učinkovitost režnje, realnočasovni nadzor stanja in samo zgodnje opozorilo na napake.

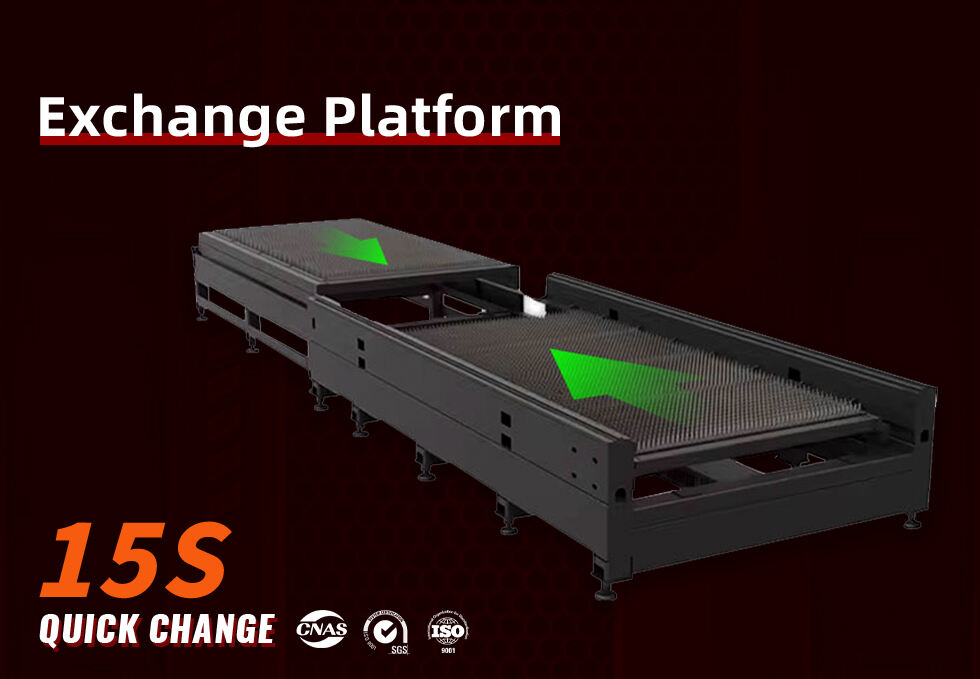

06. Učinkovita režnja: Dvojni izmenični platforma uporablja tesljivo ločeno podlago za težke plošče, da bi izpolnila zahteve nosivosti debelih plošč, omogočajoči sinhronizirane režne operacije za nalaganje in razalaganje, kar veliko poviša učinkovitost režnje.

Povzročna platforma

Izmenična miza je ključna komponenta steklovinskega laserjskega rezalnika, sestavljena iz dveh platform in pripadajočih avtomatizacijskih sistemov. Ta lastnost omogoča operatorjem, da med režnim procesom zamenja delove na drugi platformi brez ustavitve operacij. S samodejno izmenično mizo lahko operatorji pripravijo naslednji del znaprej, kar omogoča neprekinjeno reženje, pri čemer zamenjava platforme traja le 15 sekund, s tem pa se poviša proizvodnost in se zmanjša neaktivni čas.

Polna varnostna pokrov

Na prednji in zadnji strani zaščitnega plasta so nameščene vgrajene kamere, pri čemer se uporablja inteligentni središčni nadzorni sistem za spremljanje delovanja. Zadebeljeni kovinski zaščitni plast, varna proizvodnja.

Čist in varn proizvodilni okolje

Polno zaklenjena struktura je opremljena z posebnim laserjskim zaščitnim vizualnim oknom za odstranjevanje prahа, ki strogo spoštuje evropske okoljske standarde.

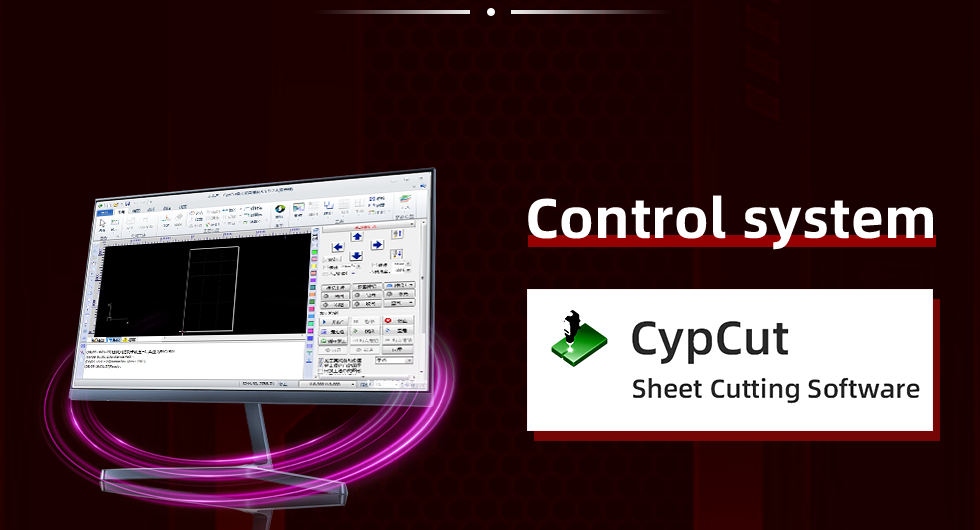

Nadzorni sistem

Opravilo rezanja listov CypCut je globoko izdelano za potrebe industrije fiber laserja, poenostavi kompleksno delovanje CNC strojev in vsebuje v enem integrirane module CAD, Nest in CAM. Od risanja, postavljanja do rezanja delovin vse lahko storite z nekaj klikmi.

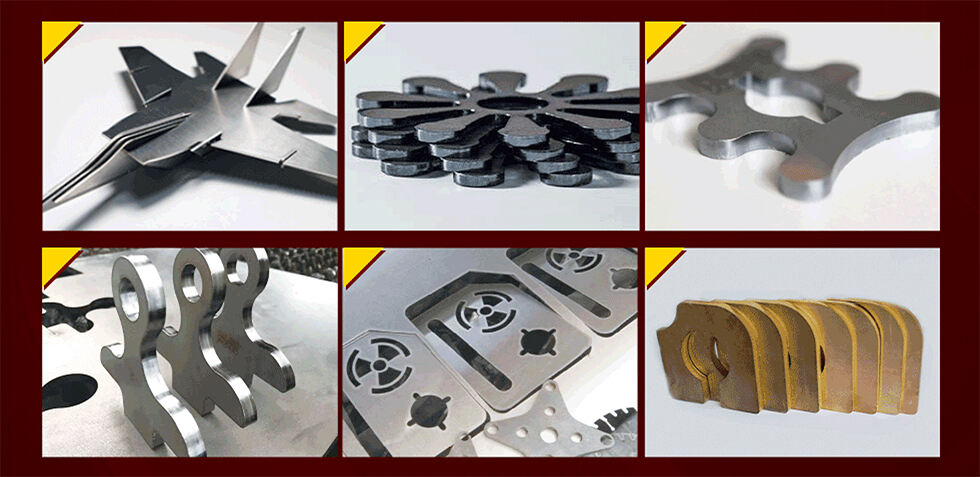

Oprema za reženje z vlaknovitim laserjem je primerna za reženje kovin, kot so nerdzava celozemelj, normalna celozemeljska plošča, ogljična celozemelj, lepljiva celozemeljska plošča, predinjava, železna plošča, galvaniziran predinjava, galvanizirana plošča, aluminijevna plošča, bakren plog, bronzasta plošča, bronasta plošča, zlatna plošča, srebrna plošča, titanova plošča, kovinska plošča, kovinska plošča itd. Različne debeline reženja odvisijo od izbire različnih moči lasera v stroju za reženje listove kovine.

|

Model |

XM-3015PH(4015/6015/4020/6020/6025) |

|

Delovno območje |

2500*6000/1500*3000/1500*6000/2000*6000(mm) |

|

Laserska moč |

1500W/12000W/3000W/6000W/12KW/30KW itd. |

|

Metoda hlađenja |

Varstvo pred vročino z vodo |

|

Natančnost pozicioniranja |

±0,01mm |

|

Maksimalno pospeševanje |

1G-2G |

|

Kompatibilno programska oprema |

CorelDraw/AutoCAD/Photoshop/Al itd. |

|

Sistem prenosov |

Dvojni tip rešetke in črpanja |

|

Strojni napetost |

220V\380V |

|

Laser Source |

Raycus/MAX/IPG/RECI |

|

Rezni sistem |

Cypcut/Raytools |

Uporablja se v obdelavi listne jake, letalstvu, vesoljski industriji, elektroniki, elektroaparaturi, metrovičnih delih, avtomobilski industriji, žitarstvu, tekstilni opremi, strojništvu, natančnih delih, ladje, metalurgiji, liftih, gospodinjskih aparatah, zanosti in darilnih predmetih, orodništvu, dekoracijah, oglaševanju, kovinski obrati, kuhinjski obrati ter drugih proizvodnih in obdelovalnih industrijah.

1. Garancija za 1 leta.

2. Održavanje celotnega življenjskega cikla.

3. Vam bomo ponudili potrošninske dele po agenturski ceni.

4. 24 ur v tednu spletna storitev, brezplačna tehnična podpora.

5. Stroj je bil pred dostavo prilagojen, operacijski disk je vključen v dostavo. Če imate kaksne druge vprašanje, mi jih prosimo sporočite.

6. Imamo navodila za uporabo in CD/U disk za namestitev programske opreme, uporabo in ohranjanje stroja.

Q1. Nič ne vem o tem stroju, katere vrste strojev bi moral izbrati?

Zelo enostavno izbirati. Le nam povedajte, kaj želite storiti z CNC laserjem, nato pa vam bomo posredujali popolne rešitve in predloge.

Vprašanje 2. Kaj lahko rezuje? Kakšno je največja možna debelina za rez?

Laser za metal običajno obdeluje oksidno celico, nerjavo celico, aluminij, bronz in spoje. Največja debelina se razlikuje med različnimi modeli in materiali. Preverite stran z uvedbo v proizvod.

Vprašanje 3. Ali lahko obiščem vašo fabriko?

Seveda. Prosimo, da nas kontaktirate kdorkoli. Predvidimo obisk v napredku.

Vprašanje 4. Ali imate inženirje, ki bi me/moje delavce poučili?

Da, vsakemu stranku ponujemo brezplačno videopoučevanje. Zavračamo pomoč do tiste točke, ko bo vse prav.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Pravilnik o zasebnosti - Blog