Découpe au Laser Fibre : Le Meilleur Choix pour la Fabrication Métallique

Dans l'industrie de la fabrication métallique, la précision de la découpe, la vitesse et l'efficacité sont des facteurs clés qui déterminent la productivité et la compétitivité. Avec le développement continu de la technologie laser, la découpe au laser fibre est devenue la technologie de choix pour de nombreuses entreprises de fabrication métallique. Machine de découpe laser à fibre ne fournit pas seulement une qualité de découpe exceptionnelle, mais augmente également l'efficacité de production et réduit les coûts. Pourquoi est-ce que machine de découpe laser à fibre est considéré comme le meilleur choix pour la fabrication métallique ? Explorons ses avantages.

Avantages de Machine de découpe laser à fibre

Comparé aux méthodes traditionnelles de découpe, la découpe au laser fibre offre de nombreux avantages, en particulier dans le secteur de la fabrication métallique.

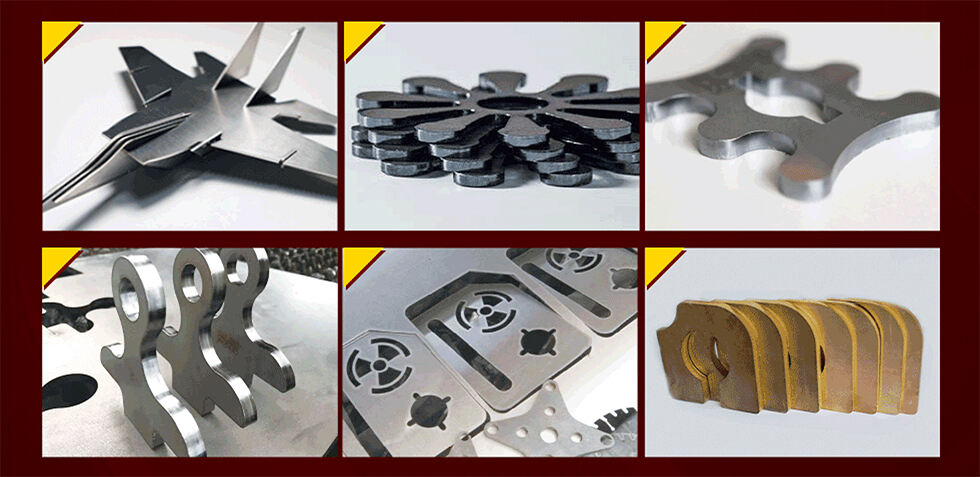

Haute Précision : Machines de découpe laser à fibre offrent une précision de découpe extrêmement élevée, permettant facilement d'obtenir des motifs géométriques complexes, les rendant idéales pour des projets nécessitant une grande précision et un travail délicat.

Vitesse de Coupe Rapide : L'usinage au laser fibre est extrêmement rapide, en particulier pour les matériaux minces, augmentant considérablement l'efficacité de production. Contrairement aux méthodes traditionnelles de découpe, la découpe au laser connaît un usure mécanique minimale et peut maintenir une vitesse de découpe élevée pendant de longues périodes.

Polyvalence : Machine de découpe laser à fibre peut traiter une large gamme de métaux, y compris l'acier inoxydable, l'aluminium, l'acier au carbone, le cuivre, le laiton et plus encore. Il peut découper différentes épaisseurs de matériaux métalliques, ce qui le rend adapté aux industries comme l'automobile, l'aéronautique, les appareils ménagers et la fabrication de machines.

Coûts d'exploitation faibles : Bien que l'investissement initial puisse être plus élevé, les machines de découpe au laser fibre ont des coûts de maintenance faibles, sont économes en énergie et réduisent le travail manuel, ce qui fait que leurs coûts d'exploitation à long terme sont inférieurs et offrent un meilleur retour sur investissement.

Bords lisses : La découpe au laser fibre offre des bords lisses, éliminant ainsi la nécessité d'un traitement secondaire et réduisant le temps et les coûts aux étapes suivantes.

Xianming Laser Machines de découpe laser à fibre

En tant que fabricant de premier plan d'équipements de découpe laser, Xianming Laser s'engage à fournir des solutions de découpe au laser fibre efficaces, précises et fiables. Nos machines de découpe au laser fibre offrent les avantages suivants :

Précision exceptionnelle de découpe : Que ce soit des coupes droites simples ou des motifs complexes, notre équipement garantit une grande précision pour répondre aux besoins de divers secteurs industriels.

Précision exceptionnelle de découpe : Que ce soit des coupes droites simples ou des motifs complexes, notre équipement garantit une grande précision pour répondre aux besoins de divers secteurs industriels.

Fort volume de production : Avec des vitesses de découpe élevées et une puissance de sortie importante, nos machines accomplissent un grand nombre de tâches de découpe en peu de temps, augmentant considérablement l'efficacité de production.

Fort volume de production : Avec des vitesses de découpe élevées et une puissance de sortie importante, nos machines accomplissent un grand nombre de tâches de découpe en peu de temps, augmentant considérablement l'efficacité de production.

Compatibilité avec une large gamme de matériaux : Nos machines peuvent découper une variété de métaux, y compris l'acier inoxydable, l'aluminium, le cuivre et plus encore, avec d'excellentes performances sur différents matériaux.

Compatibilité avec une large gamme de matériaux : Nos machines peuvent découper une variété de métaux, y compris l'acier inoxydable, l'aluminium, le cuivre et plus encore, avec d'excellentes performances sur différents matériaux.

Performances fiables : Machines de découpe laser Xianming utilisent une technologie avancée de laser fibre, assurant une haute stabilité, des taux de panne faibles et une opération fiable à long terme.

Performances fiables : Machines de découpe laser Xianming utilisent une technologie avancée de laser fibre, assurant une haute stabilité, des taux de panne faibles et une opération fiable à long terme.

Fonctionnement intelligent : Notre équipement est équipé d'un système d'exploitation intelligent, simplifiant le processus de fonctionnement et améliorant la productivité globale.

Fonctionnement intelligent : Notre équipement est équipé d'un système d'exploitation intelligent, simplifiant le processus de fonctionnement et améliorant la productivité globale.

Pourquoi choisir Xianming Laser ?

En choisissant Xianming Laser avec les machines de découpe au laser fibre de Xianming, vous bénéficiez non seulement d'une grande précision et d'une efficacité, mais vous avez également accès à un support technique de haut niveau et à un service après-vente de qualité. Que ce soit pour le choix du matériel, l'installation ou l'entretien continu, notre équipe professionnelle vous fournira un soutien complet pour garantir que votre équipement fonctionne à pleine performance.