Hello, friends. Heard only about laser welding machines? They are wonder-working tools that allow for two metals to adhere to each other, where one seemingly floats. There is a lot of them but the question arises, how do we know which one to use according to our needs? Don’t worry. In this article, we will accompany you to explore the laser welding machine and how to choose a suitable one.

What Is Laser Welding Machine?

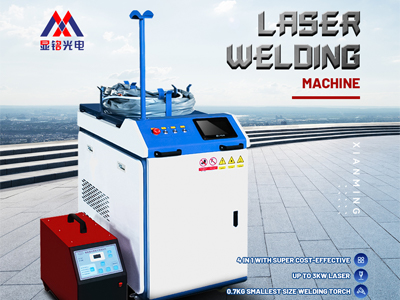

The laser welding machines by Liaocheng Xianming is a best device for joining different type metal. These consist of strong lasers concentrating on metal parts to cause the material to melt and becomes part of one in entirety. There are different types of Laser Welding Machine available today-different from what they were at the time. So knowing which machine could be the best one for our project.

Things to Think About ·

Here are a few critical points we need to be very vigilant about laser welding machine for sale word. Below are some crucial elements

Deciding on the type of metalFirst and foremost, which kind of metals will we weld. Note: Not all types of metals may be compatible with some laser welding machines so select wisely.

Thickness of the Metal: Second, we need to consider the gauge of the metal you want to weld. However, the tool is available in a variety of machines for different thicknesses of metals and we must select one according to the thickness of the metal we are dealing with.

Laser Power: Next up in consideration of what is most important to getting an accurate etch. We will have a good laser that has tough sufficient charms to line up them with the thickness of metals. And if the laser is too focused or weak, it will simply fail to melt metal.

Budget: Lastly, determine how much we want to put aside. The problem is to buy a machine within budget — for this we need to search the one that offers the best functionality and give productive result.

Choosing the Best Plow

Now that we know what is important, let's get to how do we find the best machine for our project. If we only look into the metal type that we are going to weld, these following could be the suggestions.

If you need to mill the thin metals such as stainless-steel or aluminum, then a fiber laser welding process is the ideal system for you. For all of these softer materials, it works really well.

You may want to consider a CO2 laser welding machine if you are working with steel or titanium (thicker materials) because it provides more power for thicker material.

For those trickier metals like gold and copper, there's an alternative: a welder that uses pulsed lasers instead of a beam. This made machine for worst material these are required to be handled here.

Hybrid Laser Welding Machine (for metals and plastics) This unique machine can run with two different materials.

Selecting the Perfect Machine

We need to do Research, make sure we choose the right one before we come to laser weld machine. Here are some helpful tips:

If nothing else, get these from friends and ask others that weld what would work well. Based on the general knowledge, they can be good candidates for these are most likely to know.

Then, I read reviews of that machine from the net as to plan b for purchasing that machine. Their experiences can offer us an insight.

It is also advisable to inquire about their warranty and how they treat the customer_loader as well. The seller should have a hand available to guide us to alleviate all doubts or solve any problems that will arise after our purchase.

Tech Machine key features

In short if you know that you have invested in laser welding more machine advanced and high tech then we simply need to go for some extra features that can help us even working. We can consider the below features :

Their installation offers us a camera… if used for accurate welding, helping them to achieve consistent results every single time.

The touch screen interface also paves the way for a more streamlined user experience when using the machine.

Our work rate is fast and accurate due to automatic loading and unloading systems which speed up our workflow.

High-tech machines are a bit pricier (with respect to low-cost versions), yet they will yield better outcomes and also conserve you time and effort.

Dear friends and finally selects which suitable machine for laser welding the project is just a headache. However, if we meditated on our work and which aspects were most relevant, derived the ideal machine for a project to and looked it up for a little tutorial so we could start looking specialized features deliberately. Well just remember our support during this journey in which we work even for each other. Shall we just staple them together now that we engage and attach items by the laser welding machines?