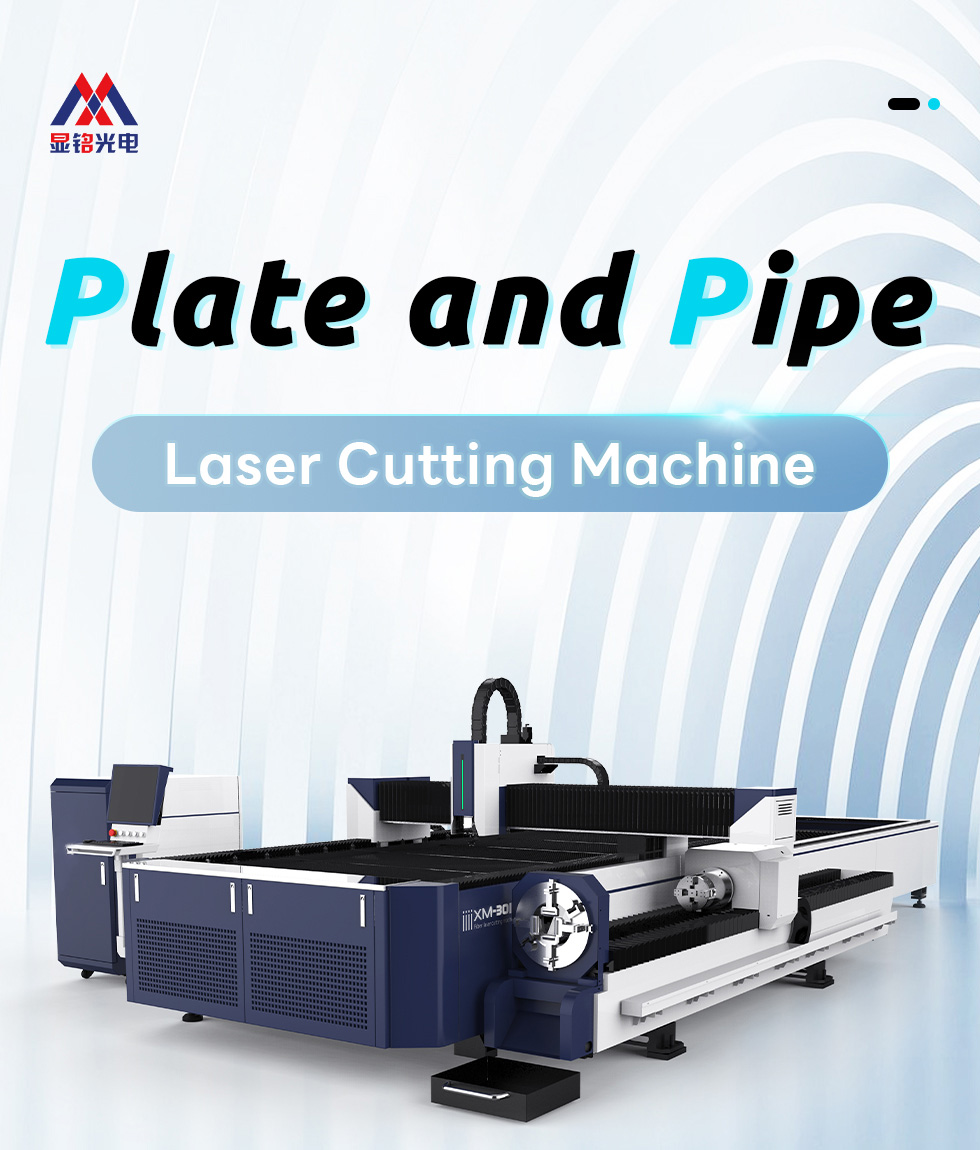

Model: XM3015FT

Working area: 3000x1500mm with exchange platform

Save purchase cost

One machine with multiple functions

Save work space

Integrate sheet and tube for efficient cutting

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

1.Whole film packaging Sheet fiber laser machine; 2.Anti-collision package edge; 3. Fumigation-free plywood wooden box and pallets with iron binding belt. |

|

Delivery Time: |

7-40 Days |

|

Payment Terms: |

TT (Telegraphic Transfer), Western Union, Paypa, Alibaba Trade Assurancel. |

|

Supply Ability: |

300 Set/Sets per Month |

|

Minimum Order Quantity: |

1 |

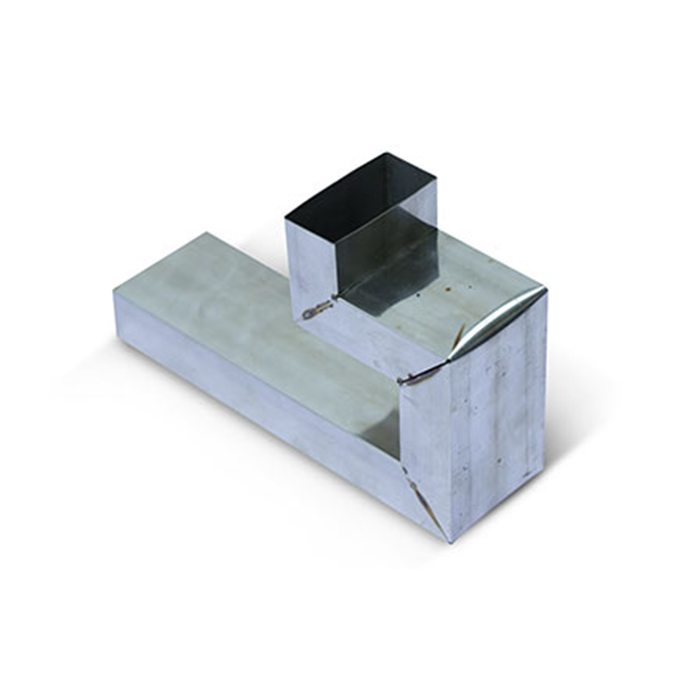

This machine can process both metal sheets and metal tubes, significantly saving on purchase costs and space. The tube length can be selected from 3 meters or 6 meters.The machine features a heavy-duty cast iron bed that ensures no deformation for up to 20 years and an aviation-grade aluminum beam for stable operation.Additionally, the fully automatic dual-start chuck is robust and durable. The machine is also equipped with imported transmission components, providing high precision.

The tube length can be selected from 3 meters or 6 meters.The machine features a heavy-duty cast iron bed that ensures no deformation for up to 20 years and an aviation-grade aluminum beam for stable operation.

VERSATILE CUTTING

The laser head enables high-precision cutting of both plates and tubes, ensuring smooth, burr-free edges.

AUTO-FOCUSING

Equipped with automatic focusing capabilities, the laser head adjusts the focus based on different materials and thicknesses, enhancing cutting efficiency and quality.

HIGH POWER OUTPUT

Provides stable high-power output suitable forcutting metals of various thicknesses.

SUPERIOR COOLING

Advanced cooling system ensures the laser head maintains a stable temperature during prolonged operation, extending its lifespan.

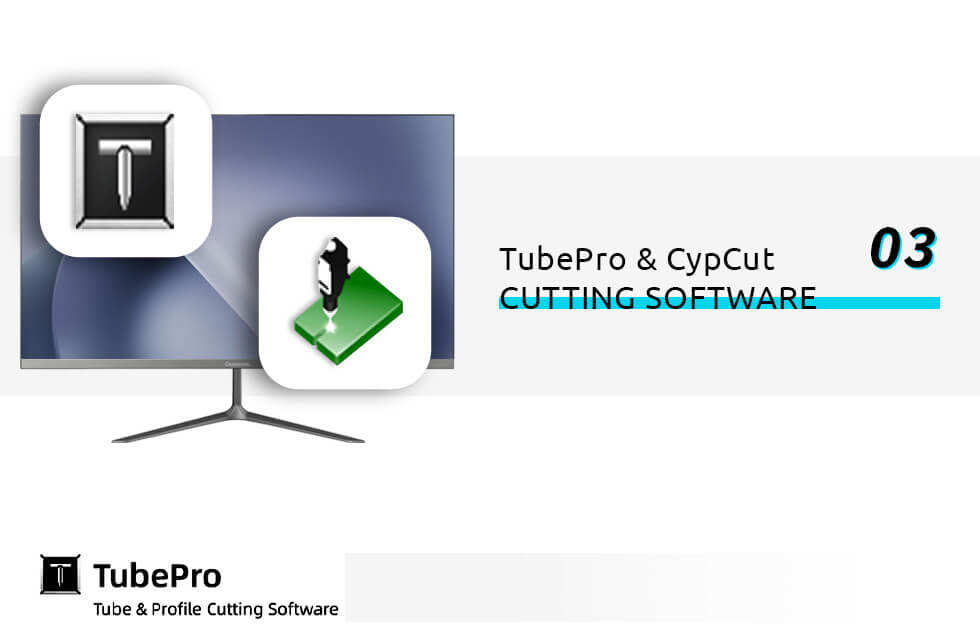

TubePro designed for professional tube cutting, supports production of tube and profile of various shape. It works with TubesT nesting software seamlessly to realize technique setting, advanced toolpath generation and nesting for standard and special production need.

01 Auto Find Tube Center in Production

02 Workpiece and Floating Coordinates

03 Seven-Axis Tube Delivering

04 Tube Holder

05 Corner Technique

06 Active Control at Corner Cutting

07 Quick Frog-Leap

08 Free Form Tube & Profile Production

The exchange table is a critical component of the fiber laser cutting machine, consistingof two platforms and associated automation systems.This feature allows operatorsto swap work pieces on the alternate platform during the cutting process without halting operations. With the automatic exchange table system,operators can prepare the next work piece in advance,enabling continuous cutting,the exchange platform only takes 15 seconds for each exchange,operations and thus enhancing production efficiency while minimizing downtime.

Integration of board cutting and pipe cutting functions, economical and practical,easy to cope with diversified processing needs.

Easy to use, low operating cost, very suitable for users of metal sheet and tube cutting.

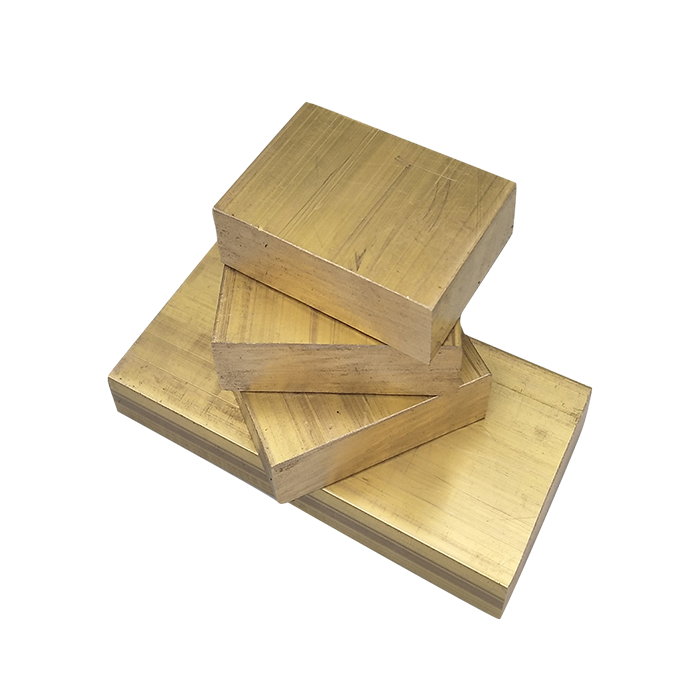

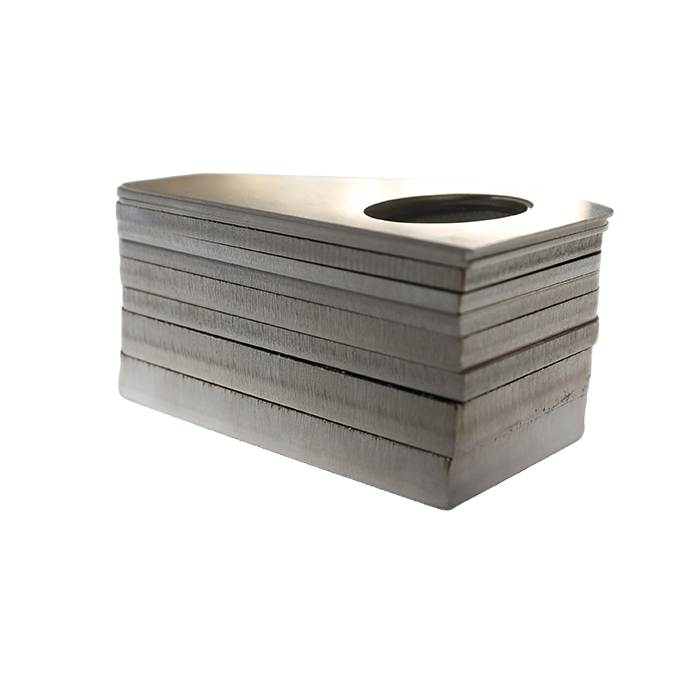

Applicable materials: Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, Titanium, Galvanized Sheet, Silicon Steel, Galvanized Steel Sheet, Other Metal Alloys...

|

Model |

XM-3015 plate and tube integrated fiber laser cutting machine |

|

Working Area |

3000x1500(mm) |

|

Laser Power |

1000W/1500W/2000W/3000W/6000W/8000W/12000W etc. |

|

Working table |

Sheet and Tube |

|

Cutting head |

Raytools/Precitec/WSX/OSPRI |

|

Maximum acceleration |

1G |

|

Max Running Speed |

120m/min |

|

Laser source |

Max/Raycus/IPG |

|

Voltage |

380V three-phase |

|

Graphic Format Supported |

AI、BMP、Dst、Dwg、DXF、DXP、LAS、PLT |

|

CNC System |

TubePro & Cypcut |

1. Fast cutting speed, high efficiency, safe operation, and stable performance.

2. The spot quality is good, the deformation is small, the appearance is smooth and beautiful.

3. Adopting imported servo motors and guide rails, and it has high cutting accuracy

4. Professional software to design various graphics or text for immediate processing, flexible processing, simple and convenient operation.

1. Warranty for 1 years.

2, Maintenance for whole life.

3, We will provide the consumable parts at an agency price.

4, 24 hours online service,free technical support.

5, Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6, We have manual instruction and CD/U disk for software installation,operation and machine's using and maintenance.

Q1. I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.

Q2. What can it cut? How thick can it cut at most?

Laser machine for metal usually deal with carbon steel, stainless steel, aluminum, brass and alloy. The maximum thickness is different between different models and materials. Please check in the product introduction page.

Q3. Can I visit your factory?

Of course.Please contact us any time . We will arrange in advance.

Q4. Do you have engineer to teach me/my workers?

Yes, we offer free video training for each customer. We promise to help until everything gets right.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog