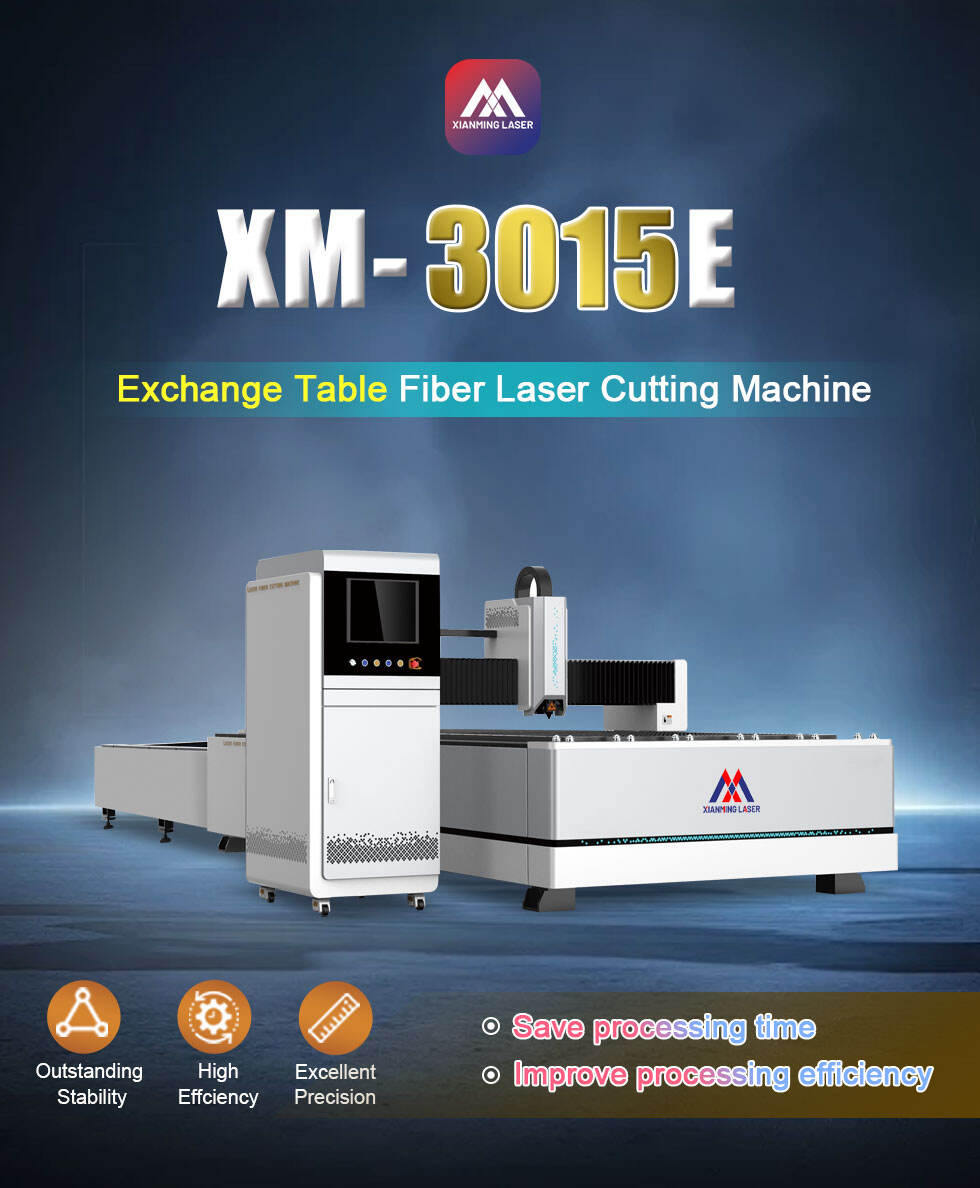

Model: XM-3015E

Working area: 3000x1500mm with exchange platform

Outstanding Stability

High Effciency

Excellent Precision

Save processing time

Improve processing efficiency

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

1.Whole film packaging Sheet fiber laser machine; 2.Anti-collision package edge; 3. Fumigation-free plywood wooden box and pallets with iron binding belt. |

|

Delivery Time: |

7-40 Days |

|

Payment Terms: |

TT (Telegraphic Transfer), Western Union, Paypa, Alibaba Trade Assurancel. |

|

Supply Ability: |

300 Set/Sets per Month |

|

Minimum Order Quantity: |

1 |

XianMing Exchange table Fiber laser cutting machine offers enhanced production efficiency and flexibility by enabling automatic table swapping for continuous processing, reducing downtime, and accommodating various materials and workpiece sizes.

01. High Efficiency Production: Utilizes advanced fiber laser technology for rapid cutting speeds and efficient production capabilities.

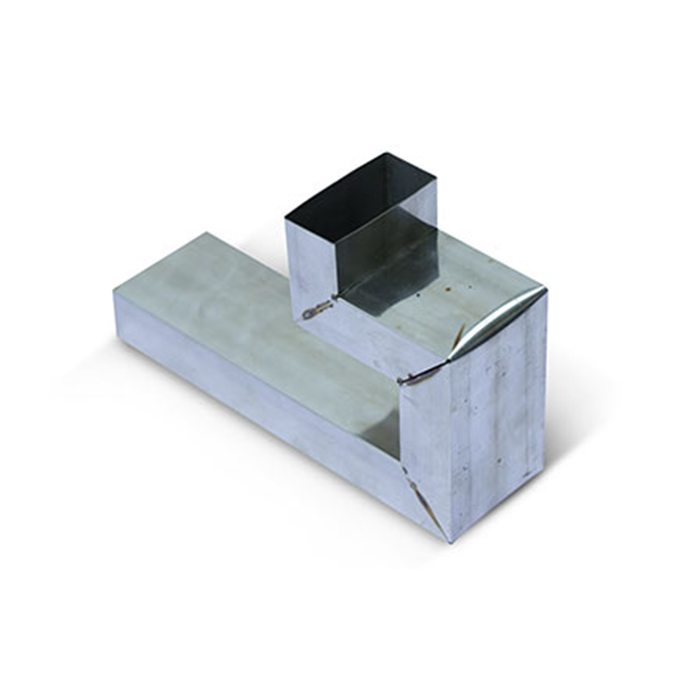

02. Flexible Processing: Equipped with an automatic exchange table system for continuous processing, enhancing productivity and supporting rapid cutting of multiple materials.

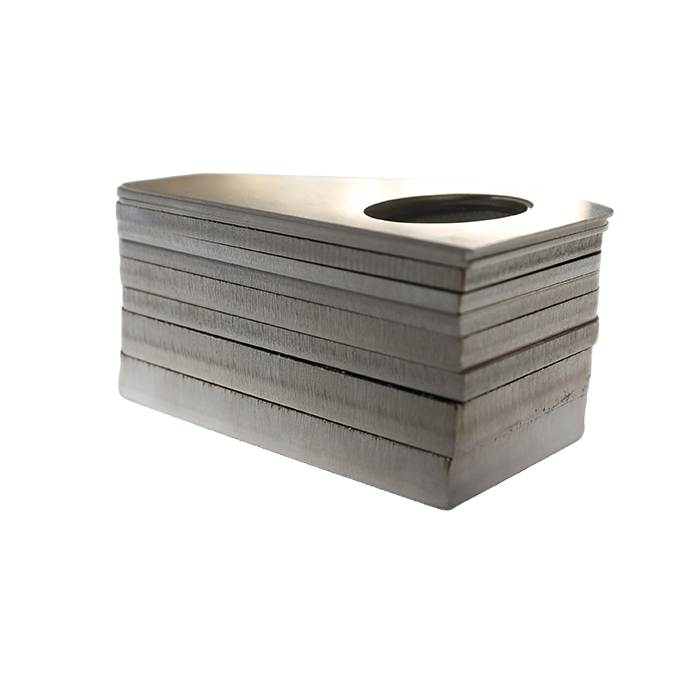

03. Precision Cutting: Laser cutting technology ensures precise cutting with high quality and accuracy, suitable for complex shapes and fine processing.

04. Intelligent Operation: User-friendly interface and intelligent control system make operation simple and easy to master.

05. Energy-saving and Environmentally Friendly: Fiber laser technology eliminates the need for chemical agents, resulting in no emissions of exhaustd gases or wastewater, meeting environmental requirements.

06. Durable and Stable: Robust structure and high stability ensure long-term continuous operation with minimal risk of failure, extending the equipment's lifespan and reliability.

07.Wide Application: Ideal for cutting metal materials such as steel, aluminum, and copper, widely used in industries including mechanical manufacturing, automotive parts, and electronics.

Higher Production Efficiency: Equipped with an automatic exchange table system, it enables automatic table swapping and continuous processing, significantly boosting production efficiency.

Enhanced Flexibility: The exchange table allows for more flexible operations by preparing the next workpiece while the current one is being processed, reducing downtime and improving equipment utilization.

Diverse Processing Capabilities: With the exchange table, the machine canaccommodate various materials and different-sized workpieces, facilitating continuous processing of different workpieces on the same equipment, enhancing production versatility.

Reduced Labor Costs: The automatic exchange table system reduces manual intervention and table changeover time, thereby lowering labor costs and improving production efficiency and cost-effectiveness.

Improved Production Continuity: The automatic exchange table system enables continuous processing of different workpieces, minimizing equipment downtime and waiting time, thus enhancing production continuity and stability.

CypCut sheet cutting software is an in-depth design for fiber laser cutting industry. It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished byafeclicks.

1. Auto Optimize Imported Drawing

2. Graphical Cutting Technique Setting

3. Flexible Production Mode

4. Statistic of Production

5. Precise Edge Finding6.Dual-Drive Error Offset

INTELLIGENT AUTOMATICEXCHANGE TABLE

The exchange table is a critical component of the fiber laser cutting machine, consistingof two platforms and associated automation systems.This feature allows operatorsto swap work pieces on the alternate platform during the cutting process without halting operations. With the automatic exchange table system,operators can prepare the next work piece in advance,enabling continuous cutting,the exchange platform only takes 15 seconds for each exchange,operations and thus enhancing production efficiency while minimizing downtime.

Integration of board cutting and pipe cutting functions, economical and practical,easy to cope with diversified processing needs.

Easy to use, low operating cost, very suitable for users of metal sheet and tube cutting.

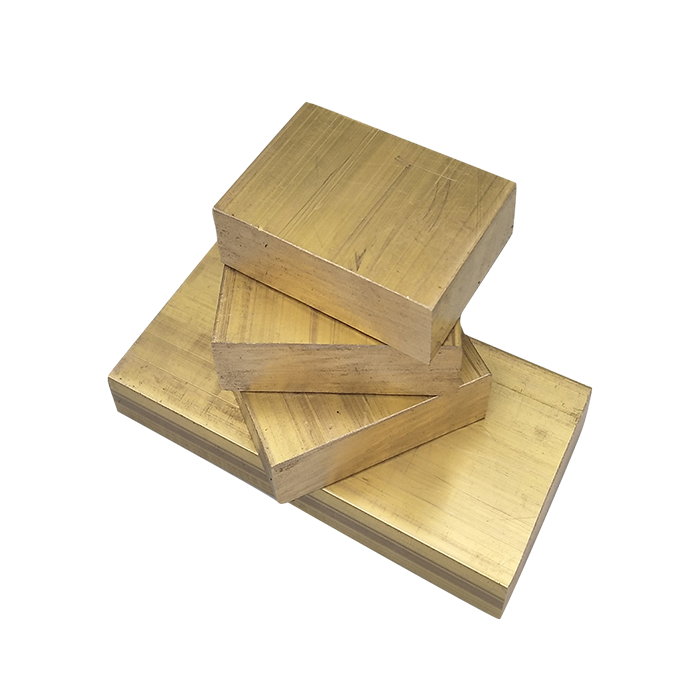

Applicable materials: Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, Titanium, Galvanized Sheet, Silicon Steel, Galvanized Steel Sheet, Other Metal Alloys...

|

Model |

XM-3015E |

|

Working Area |

3000x1500(mm) |

|

Laser Power |

2000W/3000W/6000W/8000W/12000W etc. |

|

Working table |

2(Exchanged) |

|

Repeat Repositioning Accuracy |

±0.03mm |

|

Accuracy of Positioning |

±0.02mm |

|

Max Running Speed |

120m/min |

|

Laser source |

Max/Raycus/IPG |

|

Voltage |

380V three-phase 50Hz |

|

Graphic Format Supported |

AI、BMP、Dst、Dwg、DXF、DXP、LAS、PLT |

|

Maximum acceleration |

1G |

1. Warranty for 1 years.

2, Maintenance for whole life.

3, We will provide the consumable parts at an agency price.

4, 24 hours online service,free technical support.

5, Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6, We have manual instruction and CD/U disk for software installation,operation and machine's using and maintenance.

Q1. I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.

Q2. What can it cut? How thick can it cut at most?

Laser machine for metal usually deal with carbon steel, stainless steel, aluminum, brass and alloy. The maximum thickness is different between different models and materials. Please check in the product introduction page.

Q3. Can I visit your factory?

Of course.Please contact us any time . We will arrange in advance.

Q4. Do you have engineer to teach me/my workers?

Yes, we offer free video training for each customer. We promise to help until everything gets right.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog