Model: XM-3015PH(4015/6015/4020/6020/6025)

Working area: 3000x1500mm with exchange platform

Outstanding Stability

High Effciency

Excellent Precision

Save processing time

Improve processing efficiency

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

1.Whole film packaging Sheet fiber laser machine; 2.Anti-collision package edge; 3. Fumigation-free plywood wooden box and pallets with iron binding belt. |

|

Delivery Time: |

7-40 Days |

|

Payment Terms: |

TT (Telegraphic Transfer), Western Union, Paypa, Alibaba Trade Assurancel. |

|

Supply Ability: |

300 Set/Sets per Month |

|

Minimum Order Quantity: |

1 |

It is a fully enclosed metal sheet fiber laser cutting machine with exchange platform. Equipped with fiber laser source of power from 1.5kw to 30kw, it is able to cut up to 25mm metal sheet. And the working area is from 3000mm*1500mm to 6000mmx2500mm.The fully-protected closed design ensures the safety of processing. It has the advantages of fast cutting speed, good cutting effect, low operating cost, and good stable processing ability. This cnc laser cutter is equipped with an international mainstream transmission drive system, new generation of welding machine bed and aluminum beams, new designed air circuit control module, new optimized control system and etc., The laser cutting machine is equipped with a new advanced fiber laser and laser cutting head, with superior comprehensive performance.

01. Upgraded mechanical structure: : Ultra light aluminum crossbeam, produced using 10000 ton extrusion technology to create aluminum crossbeams; Fire resistant, high temperature resistant, and excellent operational stability.

02. High-precision transmission system: The machine adopts a servo double-drive gantry structure, rack guide rail transmission, and the machine tool transmission system parts are imported brands to ensure the equipment's long-term high-speed cutting accuracy.

03. Safety And No Pollution: Fully enclosed structure with special laser protection visual window, the smoke generated by cutting can be quickly eliminated, environmentally friendly and pollution-free.

04. Monitored Control System: During the processing, each area can be monitored at any time and the process can be controlled.

05. Automatic focusing cutting head: Automatic focus adjustment, suitable for planting focal length; Non sensory perforation, flexible cutting. High cutting efficiency, real-time monitoring of status, and only early warning of faults.

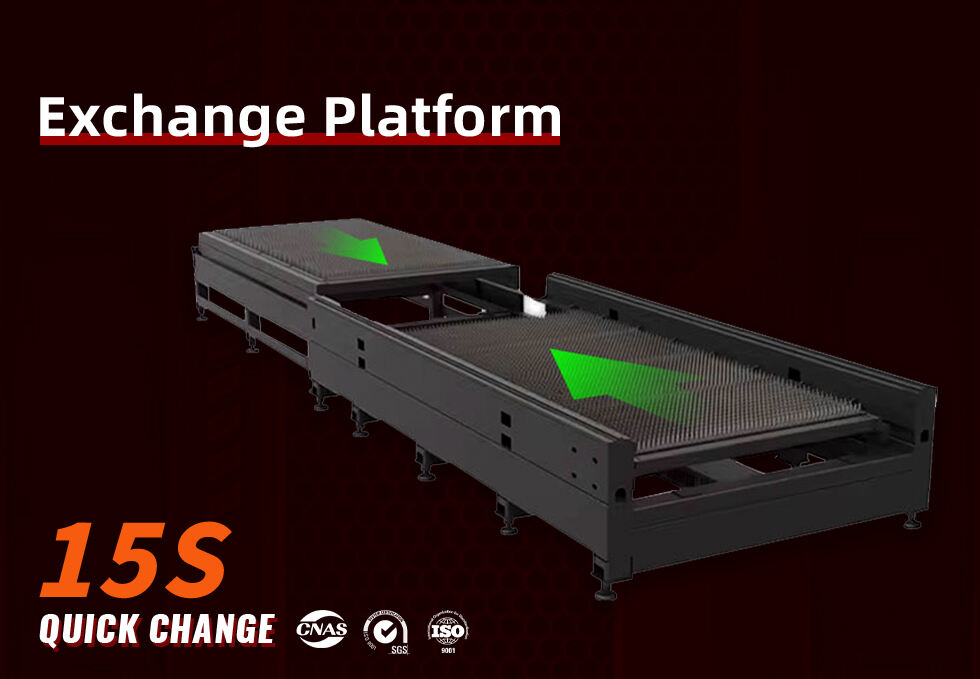

06. Efficient cutting: The dual exchange platform adopts a heavy-duty plate welded bed body to meet the load-bearing requirements of thick plates, realizing synchronous cutting operations for loading and unloading, greatly improving cutting efficiency.

Exchange Platform

The exchange table is a critical component of the fiber laser cutting machine, consisting of two platforms and associated automation systems.This feature allows operators to swap work pieces on the alternate platform during the cutting process without halting operations. With the automatic exchange table system.operators can prepare the next work piece in advance,enabling continuous cutting,the exchange platform only takes 15 seconds for each exchange,operations and thus enhancing production efficiency while minimizing downtime.

Full Protection Cover

There are built-in cameras at the front and rear of the protective cover, and an intelligent central control system is used to monitor the operation. Thickened sheet metal protective cover, safe production.

Clean and safe production environment

The fully enclosed structure is equipped with a special laser protection visual window dust removal system, which strictly complies with EU environmental standards.

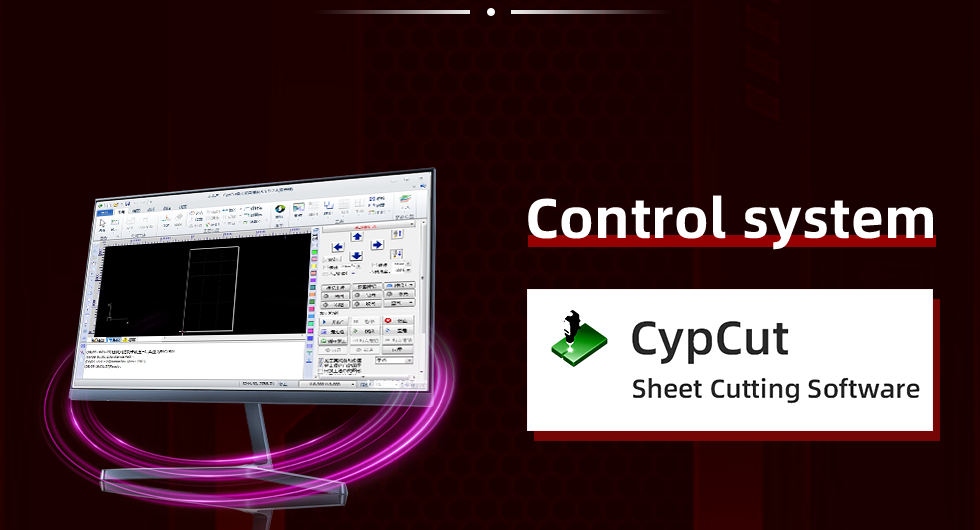

Control system

CypCut sheet cutting software is an in-depth design for fiber laser cutting industry, It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can befinished by a few clicks.

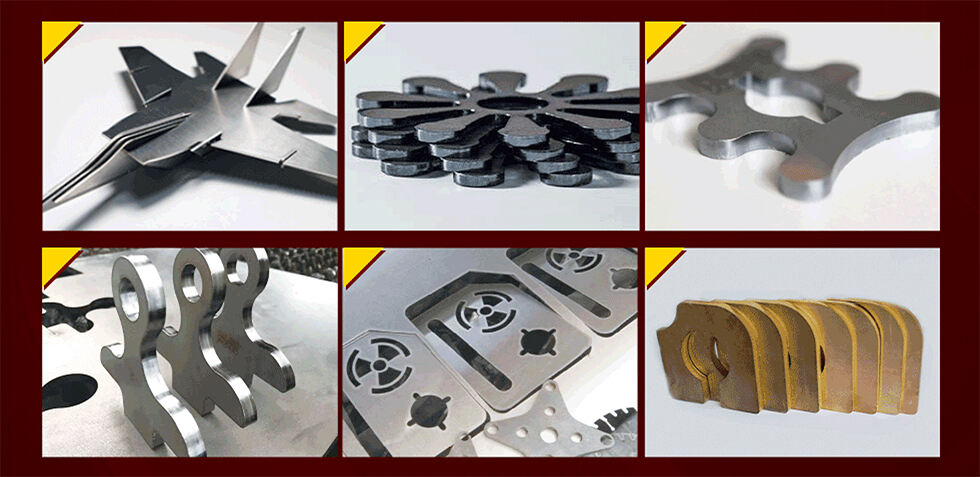

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel, Mild Steel Plate, Carbon Steel, Alloy Steel Plate, Spring Steel, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet,Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc. Different cutting thickness depends on different laser power selection in sheet metal laser cutting machine.

|

Model |

XM-3015PH(4015/6015/4020/6020/6025) |

|

Working Area |

2500*6000/1500*3000/1500*6000/2000*6000(mm) |

|

Laser Power |

1500W/12000W/3000W/6000W/12KW/30KW etc. |

|

Cooling Method |

Water cooling protection |

|

Positioning Accuracy |

±0.01mm |

|

Maximum Acceleration |

1G-2G |

|

Compatible Software |

CorelDraw/AutoCAD/Photoshop/Al etc. |

|

Transmission System |

Dual Rack & Pinion Type |

|

Voltage |

220V/380V |

|

Laser Source |

Raycus/MAX/IPG/RECI |

|

Cutting System |

Cypcut/Raytools |

Used in sheet metal processing, aviation, aerospace, electronics,electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal processing, kitchen processing and other manufacturing and processing industries.

1. Warranty for 1 years.

2, Maintenance for whole life.

3, We will provide the consumable parts at an agency price.

4, 24 hours online service,free technical support.

5, Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6, We have manual instruction and CD/U disk for software installation,operation and machine's using and maintenance.

Q1. I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.

Q2. What can it cut? How thick can it cut at most?

Laser machine for metal usually deal with carbon steel, stainless steel, aluminum, brass and alloy. The maximum thickness is different between different models and materials. Please check in the product introduction page.

Q3. Can I visit your factory?

Of course.Please contact us any time . We will arrange in advance.

Q4. Do you have engineer to teach me/my workers?

Yes, we offer free video training for each customer. We promise to help until everything gets right.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog